Share

They say it was the pockets common to machinists’ outfits at the time. The original dimensions of Modern Machine Shop were chosen to allow the machinist of 1928 to carry the magazine not only in the side pocket of a shop coat but also in the chest pocket common to machinists’ aprons. While the publication is no longer that small size today (we first changed its dimensions in 2008, then again this year), many readers of MMS still keep the magazine close at hand, and even close to their heart.

They really do. I am biased, of course, but the frequency with which we hear from readers who honor us by describing their appreciation for the publication and its work over the years leaves me persuaded that MMS is more than just an industry trade magazine. I believe the reason for the affection and loyalty the magazine has earned is the priority that this magazine has had from the beginning, the priority that focused on those very pockets in the machinists’ clothes: an aim to belong to this industry. Those of us who produce MMS work for a media company, Gardner Business Media, the very same family company that has owned this magazine since its founding. However, at the encouragement of owners of this company, we give our primary sense of allegiance to metalworking rather than to our own field of media or publishing. The business philosophy of MMS has always been this: Focus on manufacturing—aim simply to be of greater and greater usefulness to manufacturers—and success will come. It has worked so far.

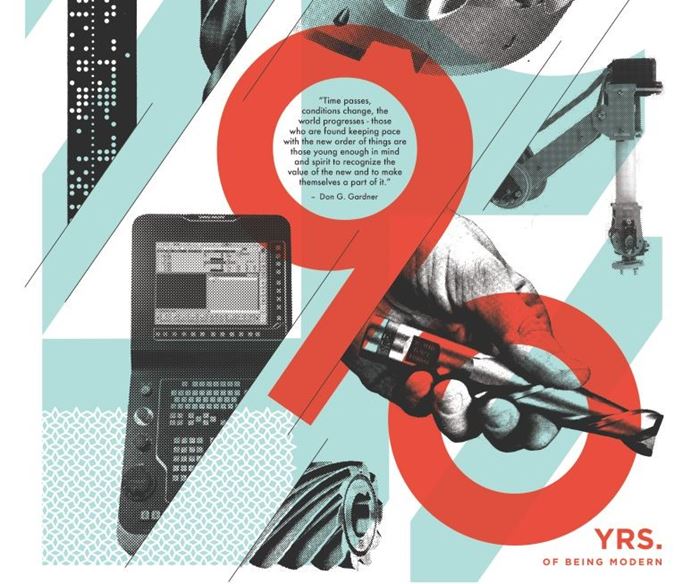

The June 2018 issue marks 90 years of Modern Machine Shop magazine. We wanted to celebrate. We wanted to observe the milestone. Enough of us involved with MMS have long-enough tenure that we remember the 75th and 80th anniversaries, which we allowed to pass only lightly considered. We wanted to do better this year, but how? Should we look back at the magazine’s major milestones? Maybe.

The problem with that approach is the events we would be apt to choose—major issues of the magazine, changes in media, transitions on the editorial team—would seem significant to us, the staff. The MMS reader also experiences milestones that involve this magazine, but they are different. They relate to ideas explored and technologies adopted because of what the reader found in these pages. We never get to know which specific magazine issues offer the breakthroughs for our readers because the important discoveries, the right ideas that come at just the right time, are different for every shop. What our readers appreciate about MMS and what they benefit from are its regular issues.

So that is the way to look back. In this special collection of articles, we look beyond just epochal or event-defining issues of the magazine. Rather, we look back at regular issues of Modern Machine Shop out of the many decades of the magazine’s history. Decade by decade, the magazine has always sought to be relevant and helpful to the metalworking business leaders and professionals of the time. What did that look like, and how does it look to us now? The staff of MMS has spent some time poring through back issues of the magazine in search of articles that highlight where manufacturing has been, as well as coverage that might have offered some of those milestones representing significant advances for shops at the time. Let us share with you what we found.

But first, on behalf of all of us involved with MMS and the company that has published it for these nine decades, let me extend my gratitude. Thank you for giving us your attention; thank you for giving us the chance to aid you in your work. Likely there is no machinist’s apron you wear today, but thank you for slipping the magazine into briefcases and carry-on bags. Thank you for passing the magazine through the office and through the shop until its covers tear and its pages become creased. Thank you for 90 great years of getting to be part of this industry.

Now, stay with us a while longer and read on. Here is what was going on in some of those 90 years….