Monitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Share

The latest machine tools are designed to be monitored, with many offering dashboard displays of critical performance metrics as a standard feature. However, getting beyond rudimentary machine monitoring capability might be easier for manufacturers that begin with more established technology: a distributed numerical control (DNC) system for transferring part programs to CNCs. “You get 90% of the way there with what comes out of the box, but you need tools for that last 10%,” says Rich Hefner, president of machine monitoring system developer FactoryWiz. “DNC is a critical tool for that.”

As an example, Hefner cites the machining of differently sized screws on Swiss-type machining centers. Rather than creating separate sets of tool paths for each size, a CAM programmer might use a macro to change a few key variables within a common program. However, he says tracking quantities and cycle times for individual screws can be complicated when monitoring is divorced from DNC.

The reason why is that many of the communication protocols employed to collect CNC data, which differ from builder to builder, would not recognize

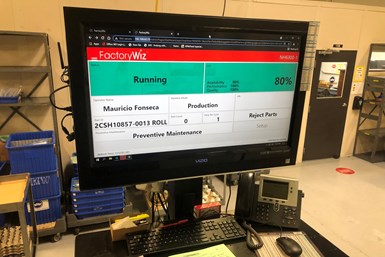

With tablets and PCs increasingly common on the shop floor, integration between monitoring and DNC can eliminate duplicate data entry (possibly at different terminals) by standardizing and consolidating processes at each workstation. Image courtesy of FactoryWiz.

the individual part programs created by the macro. Consider MTConnect. MMS has covered this standard heavily for good reason: It contributes significantly to making machine monitoring accessible by providing a common “language” for a diverse mix of machine tools and other shopfloor equipment. However, MTconnect is a read-only standard. That is, it is designed to pull data from the CNC, but not send data to it. It cannot issue the necessary command to change variables for monitoring the parts as well as machining them. Returning to the example of the Swiss-machined screws, “You’ll get the same program header regardless of which of the 50 different screws you’re making,” Hefner says.

DNC has no such restrictions. Decades ago, suppliers of these systems were experimenting with essentially reversing dataflows to gain a rudimentary level of intelligence from the shop floor. One means to this end was the DPRNT (“data print”) command, which inserted language into the G code for outputting select data to a printer via the RS232 cabled connections of the time. Modern DNC systems work in essentially the same way, he says, although the software is far more capable and user-friendly, and the connection is generally faster (and often wireless).

In any case, the ability to achieve Hefner’s “last 10%” of capability is inherent to a system born from DNC. DNC connects via the control’s native protocol, and can become a data source for machine monitoring or other analytic software. He argues that this capability can be advantageous even when it is also native to the latest, ethernet-connected CNCs. After all, machine tools in production today come from various eras.

Machine monitoring aside, shops also seem to be rediscovering the value of DNC in its own right, says Domenic Lanzillotta, vice president of sales. DNC helps institute consistent, standardized processes for the management and distribution of CNC programs, he explains. This proposition is particularly attractive for those seeking compliance with quality control certifications. Likewise, DNC can alleviate cybersecurity concerns with practices like transferring programs via USB stick. “I’ve put in more DNC systems in the last two months than I have in the last two years,” he says.

Adding machine monitoring amplifies these benefits, even when ambitions for monitoring extend no further than tracking downtime and other basic metrics. Machine monitoring has come a long way since the days of tying PLC hardware into machine tool stack lights to output DPRNT commands. Today’s software offers a range of capabilities for automatic, remote alerts and notifications, job progress tracking and even direct, text-based communication between workstations and departments. “Why not take the DNC component and include it in that same operator interface?” Hefner asks. “Why shouldn’t (the same workstation tablet or computer used for monitoring) be where they can click and select the file to send to the machine?”

Add other software to the mix, such as an enterprise resource planning (ERP) system, and workstation tablets or computers can provide a common interface for a range of different tasks, from “signing in” to jobs to notifying quality control that parts are ready. “When we started out with monitoring, we were just collecting information and giving reports, and just looking at productivity strictly from an analysis standpoint,” Hefner explains. “As we’ve gone along, we’ve really shifted to looking at this as an information hub — as infrastructure for communication within a business.”

Related Content

Easy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MorePrecision Shop Adopts Machine Monitoring, Boosts Revenue

Adopting machine monitoring helped LeClaire Manufacturing boost its vertical CNC utilization rates 38 percentage points and gain millions in revenue.

Read More