Rapid Reports Improve Shop Utilization

The owners of David Packard Company wanted to look beyond facility expansion to increase the output of the shop. They turned to Datanomix to unlock hidden capacity in their current infrastructure.

Located in Oxford, Massachusetts, David Packard Company (DPC) is a full-service, 50,000 square foot machining facility. DPC has formed relationships with a wide variety of customers in medical, defense, firearms, fiber optics, telecommunications and commercial applications. In order to keep up with demand the company manages two shifts and leverages unattended run time.

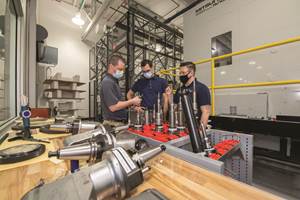

The shop has installed TVs throughout the shop to increase visibility of key metrics to the entire company. The persistent access to how the shop is performing has led to collaboration and increased productivity.

Photo Credit: David Packard Company

2020 presented new challenges for DPC as the pandemic put pressure on component suppliers to meet unforeseen demands from its customers. Tom Vinal, operations manager at DPC, commented on the company’s recent growth saying, “2020 was a record year for the company with 20% growth on, more than tripling previous years.” Vinal attributes the success to a spike in demand from its medical customers who were scrambling to meet demand for medical equipment in the midst of COVID-19. “While some customers were faced with shutdowns, others could not produce enough to meet new demand.” Vinal says.

Matt Dipietro, president and owner of DPC, sees new tailwinds in the market and is now designing a game plan for growth. One aspect of the plan includes expanding the facility but that is a long-term solution. The near-term solution is to expand its capacity by increasing usage of its current infrastructure. Dipietro commented, “I know we can unlock 20% of additional capacity from our existing base to fill the influx of new business coming in while we put plans in place to expand our facilities. We need to change the way we think about running the business and how we integrate technology into our management philosophy. It’s no longer optional.”

Software Solution in the Field

During a visit to one of its partners, J&W Swiss, Dipietro was given a tour of the shop’s implantation of Datanomix. The shop was broadcasting production scores on TVs around the factory floor. Owner, Jim Langlois, spent 30 minutes demonstrating the software and the TV broadcasting system and Dipietro was sold. DPC asked for an introduction to the Datanomix team and the first meeting happened quickly. In total, it lasted about 34 minutes. The DPC team saw the demo of the software and Dipietro asked 3 simple questions, “How much is it? What does it take to install? When can we have it?”

The factory installation took a few hours to complete. To get the system up and working the team had to ensure network connectivity between devices and set IP addresses for data access. Datanomix taps into existing network connections on modern CNC platforms.

DPC had full access to live production data the next morning through the Datanomix interface. TV monitors were mounted on the factory walls and in the cafeteria. Whether people were working or on break, they knew exactly where each job was on the floor and how it was performing compared to expected benchmarks. After an hour of training the team was off and running.

Reflecting upon where the shop was before the use of Datanomix software, there are stark differences in information flow, speed of root cause analysis, true KPI measurement and overall productivity of not only the operators, but also the entire leadership team. Dipietro sees “a combined 15% increase in shop output after implementing the Datanomix software.”

Factory Visualization and Notification System

The information disconnect between the factory floor and the offices at DPC, which are on separate floors, was nearly eliminated because every member of the shop now has access to data visualization on their monitors and smart devices. The physical distance between the office and the shop floor was a real problem. Two of the three machine experts have offices on the second floor of the shop and can now respond to a machine down situation in seconds, when in the past, it could take a few hours before information about the situation made its way up to the second flor. The lost productivity due to downtime was significant.

Datanomix has given the shop a way to confidently address systemic problems in the production process. Leaders in the company are able to partner with their machinists by assessing data and interpreting the results of change.

Photo Credit: David Packard Company

At DPC the team has created culture around their “morning coffee cup report.” This report is delivered to the staff at 6:00 am each day. Dipietro and the team use the report to collaborate on corrective action plans and it builds alignment across the organization. People who are not typically leaders get involved in problem solving and in turn begin to actively help others on the production floor. The system has driven new levels of unity amongst the operators.

Production Intelligence

Datanomix software replaces 15 different report that Dipietro and his team would run on a weekly basis with a single application. Now, they spend less time assembling data and spend more time assessing the data. Hours of time are recovered by displaying key statistics such as set-up time, tool breakage stats, first part complete times, and exact cycle times. When speaking about the statistics, Dipietro acknowledges that “The most important statistic for DPC is cycle time reporting.” Knowing the exact cycle time on a job allows Matt and his team to be very precise in quoting jobs and completion dates to customers. This predictive delivery forecasting capability alone improved factory floor efficiency.

Data Drives Management

The shop has come to depend on predictive intervention within the software to keep jobs on track. Dipietro says “We can see emerging patterns in the Datanomix information that indicates to us that a job is in jeopardy and we now proactively address it instead of waiting for things to happen and have the operator notify or ask for help. Senior machinists on the floor are working with others to help them keep their jobs locked on delivery dates and quality goals.”

Conversations are informed by data, eliminating assumptions and feelings about a given project. The reality of working with data means that the team is able to focus on changes that improve the output of the facility.

Photo Credit: David Packard Company

Production intelligence is now at the core of Packard’s management philosophy. With Datanomix they see the entire operation visualized in a single place with real data from the machines that has been processed, tabulated and displayed across the company as it’s happening. The shift in the operating culture to one where patterns of performance are recognized by the staff have driven results in a measurable way. Real-time data processing has paved the path forward for the David Packard Company to continue their growth so when they fill their expanded space, they know they’ll be performing up to expected standards and with a production management approach that maximizes efficiency of machines, people and jobs.

Related Content

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreShop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)