Resolving Four Unexpected Challenges of Mobile Robots

An automated guided vehicle (AGV) with a robotic arm on top enables medical manufacturer RMS to tend as many as eight machine tools at once. But the shop first had to deal with a few unforeseen snags in its implementation.

Share

Industry moves fast.

We make sense of what’s next.

Manufacturing Connected is a new platform from Modern Machine Shop and our sister publications. Bringing you big-picture insights that cross technology and industry boundaries.

GET CONNECTED

Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) can provide a flexible, efficient automation solution for machine shops. RMS, a medical device manufacturer, successfully integrated Staubli’s HelMo system, which consists of a mobile robotic arm mounted on an AGV base, into the production of medical devices. By tending as many as eight machines, HelMo has helped RMS save space and reduce automation costs in its pacing business unit. However, as the company discovered, the flexibility of such autonomous systems also introduced new challenges, requiring adjustments to ensure smooth operation.

Transcript

Julia Hider: Autonomous mobile robots, or AMRs and automated guided vehicles or AGVs have many potential uses in a machine shop. From tending machine tools to delivering new cutting tools, to moving away full chip bins. Autonomous robots’ ability to move around a facility means they can handle more machines than traditional fixed robots and take up less space.

Medical manufacturer RMS dreamed of finding a fully integrated, autonomous machine tending robot for years. It finally found a solution in the HelMo system from Staubli.

HelMo consists of an industrial robotic arm mounted on top of an AGV base. It follows a pre-programed path around its cell, using three area scanners to detect any obstacles and stop it if necessary. The scanners can also slow or stop the speed of the robotic arm if it detects people nearby.

RMS uses the HelMo to tend Robodrills that machine high volume medical parts. The Helmo can tend as many as eight machines. And during manned shifts, two operators for every four machine tools flip parts from the first operation to the second operation. It also runs lights out between second and first shifts, giving the shop three more hours of unattended machining time.

According to RMS, the HelMo is cheaper than having a plug and play automation system at every machine tool. It also saves space, a key consideration for a shop with 850 machine tools and more on order.

But as RMS has learned, the benefits come with trade offs. Its flexibility meant that RMS had to solve problems as they arose in order to get the system working perfectly.

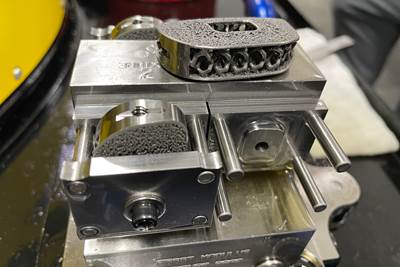

Each machine that the HelMo tends has these three studs. When the robot comes up to the machine, it scans them. And that helps the robot orient itself so it knows where it is in space, so it can begin loading and unloading. But these studs are strategically located on the machine so it can be serviced without removing them, because if the studs are removed and they aren't put back in the exact same place, that causes problems with orientation.

The team also redesigned the locating stud on its fixtures, so that these flats are always in the same position because that's what the robot grabs onto when it moves the fixtures.

The HelMo has three sensors, two on the back and one on the front. And the RMS team eventually realized that these sensors can pick up oil mist from the machines and that was affecting the navigation. So they've since had to install more mist collectors to help mitigate that issue.

One of the simplest issues they had to troubleshoot was these air hoses. People will leave them all over, on and around the machine tool, but that would cause problems with the robot's navigation. So now everybody hangs up the air hoses on a hook.

Related Content

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreRevolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

Read MoreRead Next

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreThe Four Phases of a Manufacturer’s Automation Evolution

With more and more automation options available for manufacturers, how do shops figure out what works best? Medical manufacturer rms Company has acquired robot arms, AGVs, pallet changers and software, and while it has found success with all, it has learned how some solutions meet its particular needs better than others.

Read MoreOEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More