Swiss Center Brings Paper Punching Work In-House

With a Tornos Swiss ST starter machine, Performance Design brought paper-punching component production in-house and reduce overhead costs by 66 percent.

Share

By outsourcing the manufacture of key components of its Rhin-O-Tuff brand of paper punching equipment overseas, Performance Design was losing control. Relying on outside vendors prevented the company from making what it wanted when it wanted, says Steven Parker, project engineer. After taking a closer look at its entire manufacturing process, the company decided to bring this particular work back in-house. With the help of a Swiss-type turning center from Tornos (Lombard, Illinois), the company was able to regain production control and reduce overhead costs by 66 percent.

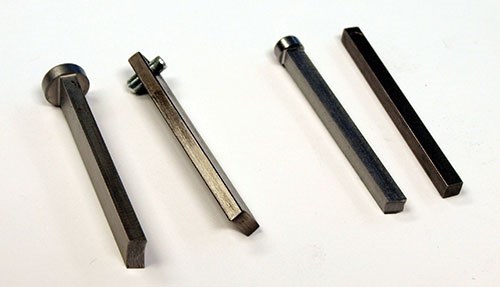

Performance Design, a 25-employee company based out of a 20,000-square-foot facility in Boise, Idaho, designs and manufactures paper punching machines for Staples, Kinkos and large corporations’ in-house printing departments. The company offers more than 20 different product lines, including Rhin-O-Tuff brand punches, tools and equipment for binding paper with plastic combs, crimped wire and spiral plastic coils. With many of its competitors based in China, Taiwan, Vietnam and Portugal where labor costs and overhead are low, Performance Design had outsourced the manufacture of round, oval, square and rectangular metal pins used to punch paper into corresponding shapes. The pins measure between 1/8 and 5/16 inch in diameter and about 2 inches long, which includes a 1/8-inch head gripped by the punch machine.

However, in late 2012, the company decided to take a new approach. “Rather than sending production offshore, we brought in lean manufacturing experts to totally reinvent the way we manufacture our products. This impacted a lot of things, from the way we order raw materials to the actual manufacturing processes of our punches and binding equipment,” says John Lugviel, VP of business development. To help implement these changes, the company needed to add a turning center to its mix of horizontal and vertical mills.

Just as Performance Design was about to purchase a new machine tool it had seen at the International Manufacturing Technology Show (IMTS), Tornos salesman Fred Huth presented specs on the Tornos Swiss ST 26 “starter” machine. The company discovered that the Tornos Swiss machine was capable of making not only the oval pins—the first component the company wanted to bring back in-house—but also the square and rectangular pins, all from the same round stock material. This was a major improvement from the square and rectangular raw material the company had been using to make its square pins. They had been adding a couple extra features, but the final pin shape was based on the raw material they got in. “We had a lot of problems with out-of-tolerance dimensions due to varying raw material,” Mr. Parker says. “But since the material had to come in such huge orders, sometimes we had to deal with it because we didn’t have time to make a new order.”

Once the company determined that the Tornos could use round material to make rectangular pins, they were hooked. Other manufacturers could match that capability, but only in the $200,000 to $300,000 price range, higher than the range that the Tornos Swiss ST offered, Mr. Parker says. “They had a couple options with polygon turning, but for our application, it just wasn’t going to be a viable option,” he continues.

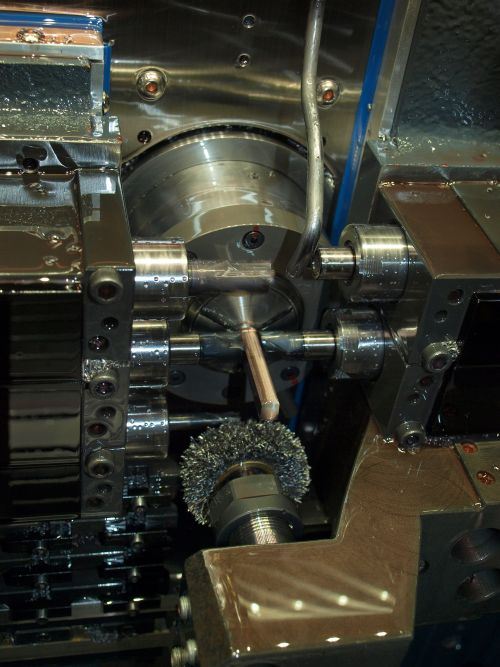

A major feature that drew Performance Design to the Tornos machine was its pinch milling capability. During normal machining, a single end mill takes the raw material from a round shape to a square cross section. However, by the third or fourth flat, nothing is supporting the cut from the other side. During pinch milling, two identical end mills basically pinch the material to support it against themselves. Without this capability, the company would have needed about seven different raw material sizes to machine 13 different pin shapes. As it stands, the company currently machines with two sizes: 1/4- and 3/8-inch round 12L14 steel.

Changing the raw material’s shape has also eliminated the need for manual labor to assemble gripper heads on the square pins. With square material, machinists drilled a cross-hole and hammered in a roll pin to act as that head, Mr. Parker explains. This process necessitated additional labor for every pin. Now, the round head is left at the end of the square pins to save labor time. While the new pin head required minor changes to the punch design, he says it is twice as strong.

Another benefit of only using two sizes of raw material is that change-over time is minimal. With the proper planning, Mr. Parker says the company only has to do a change-over once per month. The Tornos machine is equipped with enough tool slots to fit all the tooling needed to make all the pin shapes from each type of raw material at once—with spots still available. The average cycle time is 60 seconds per pin, unmanned. Cycle time for the round pins is about 36 seconds per pin, and the square pins are around 70 seconds. Even though the square pins take longer, an unmanned process is preferable to manually pounding in the roll pins, Mr. Parker says.

The final Rhin-O-Tuff pins are available in 15-pin sets to bind normal books, which require 30 to 40 holes punched along the bound length. To make it easier (and less noisy) to punch these holes, the sets are staggered in such a way that the shaft length changes slightly from pin to pin, thereby spreading punching force. These pin sets are perfect for automation, so Performance Design investigated and purchased a parts carousel with 15 bins. “Tornos helped us set it up and create a macro. Now, we just program in how many of each pin we want,” Mr. Parker says. For example, if a machinist enters 200 of each length, the machine will produce 200 of a particular length before the program’s built-in macro switches to the next length and indexes the carousel.

Eventually, the company plans to run lights-out. Producing all the pins during the evening would free the machine for parts that need more surveillance during manned hours, Mr. Parker says. Although some manufacturing is still outsourced, more will be brought in-house as the company better learns to use its new Swiss machine, he says. In fact, if all the pins were machined in-house, only 70 percent of the machine’s runtime capabilities would be realized. That leaves the machine open for future projects, including the possibility to turn the tables and take on work from others rather than outsourcing its own.

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read More