Three Divisions Under One Shop Management Program

Instead of buying multiple software packages to perform the distinctly different functions of its three separate divisions, Mt. Vernon Machine & Tool Inc. (Mt. Vernon, Ohio) selected just one package.

Share

Instead of buying multiple software packages to perform the distinctly different functions of its three separate divisions, Mt. Vernon Machine & Tool Inc. (Mt. Vernon, Ohio) selected just one package. Over a span of about 5 years, the company attended various tradeshows and other meetings in search of an integrated solution that would ostensibly streamline operations. The growing company eventually selected Visual EstiTrack from Henning Software (Hudson, Ohio) to handle tasks ranging from selling raw materials and providing welding and fabricating services to CNC machining for its machine shop, steel warehouse and retail welding supply store.

Prior to adopting Visual EstiTrack, Mt. Vernon evaluated various systems. Many software packages for the shop floor were also suitable for production runs. However, Mt. Vernon wanted to also make sure that such a system was applicable for a single part that may never repeat. One concern was having a program that would manage its retail steel division as well as its machine shop. To that end, the company decided to go with Visual EstiTrack because the system could manage both the manufacturing and financials for all three divisions.

“This has saved us thousands per year in accounting fees,” notes Gail Stenger, president at Mt. Vernon Machine & Tool Inc. “The software also allows us to run the three companies under one software system while retaining individual information by company. We now have the capability to enter a quote and automatically turn it into a shop order.”

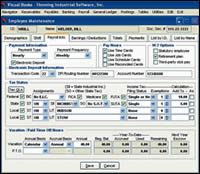

Henning’s Visual EstiTrack software handles accounting, payroll, quoting, shop orders, scheduling and inventory.

“Our shop schedule changes on a daily basis and this system allows us to modify the day’s work with ease,” Mr. Stenger says. “Formerly, inventory for our steel division was never accurate because the machine shop would consume material that was not recorded as a sale. With Visual EstiTrack, we can pull inventory for use in our machine shop and weld shops, or we can sell it directly to a steel customer. Special non-inventoried material purchases can be handled and consumed without creating an inventory item. This further streamlines our operations.”

The company abandoned each of its previous software systems as it proceeded with its division by division

implementation.

“We were not interested in incorporating these previous systems into the new Henning system,” Mr. Stenger says

Mt. Vernon did not, however, move into the new Henning system overnight. Phasing into the system enabled the Midwestern company to keep its present software running until it had the comfort level necessary to keep the business running smoothly throughout the change.

The first part of the transition was to integrate accounting and payroll into the new system. The next step was to phase in the steel division and related inventory.

“This area needed customized changes to the software and we wanted to be sure of ease of operations before continuing,” Mr. Stenger explains. “We worked with Henning to augment the existing raw material calculator found in its Sales Order module. As a result, we can now purchase and stock steel in pounds but sell to our customers in whatever unit of measure they request, including piece, square foot/inch, linear foot and pounds.”

Mt. Vernon also comments that the calculator provides a screen to define the cut sizes and quantities of the material being ordered and then returns the total price for the selected unit of measure. The company can then print a pick-list with the cut-size information.

“This capability makes it easy for us to fulfill the customer’s order from our steel warehouse,” Mr. Stenger says.

After that, the company integrated the welding supply. Last came the machine shop, because it felt that area would be the most difficult and time consuming. Since the swap, Mt. Vernon has been able to use the system to create shop orders, track labor time and schedule the machines.

“We can tag each transaction within Visual EstiTrack with the division the transaction belongs to,” Mr. Stenger says. “This means that we can easily separate our management reports by division yet share common data amongst the different divisions such as inventory, customers and vendors.”

“Visual EstiTrack helped us eliminate all of our disparate systems so that we can now operate under one integrated shop management system” he adds.

After attending Henning Software’s annual users’ conference, Mr. Stenger says he learned more details on the system’s graphical executive management reporting tools. With Visual EstiTrack’s executive summary information and business metrics, he can now keep his finger on the pulse of his company and divisions.

“Henning Software brought us up to date in terms of our information processing,” he concludes. “We have integrated all of our divisions which, in turn, has given us the tools to grow our company.

“We recently expanded our business, by adding 14,000 square feet to our existing facilities. An additional 6,000 square feet will be added this spring.”

Related Content

How I Made It: Nushrat Ahmed: CNC Swiss Operator

By day, 21-year-old Nushrat Ahmed is a CNC Swiss operator making automotive parts. By night, she handcrafts crocheted items.

Read MorePreserve the Craft of Manufacturing as Technology Advances

As the industry continues to move toward a digital future, be sure to reinforce the core fundamentals right alongside it.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More

.png;maxWidth=300;quality=90)