Share

Robotics have advanced to the point in which CNC machine shops’ expectations might outnumber questions about practical applications. In fact, many successful shops are already benefiting from machine-tending robots or have researched various robot offerings with an eye toward adding them.

Global robot sales bear out this notion. According to the International Federation of Robotics’ 2018 World Robotics Report, a record number of 381,000 robots were shipped worldwide in 2017, an increase of 30 percent compared to 2016. For 2018, that number is expected to increase by 10 percent to 421,000 robots shipped.

The maturation of manufacturing robots comes at an opportune time for shops both big and small. The lack of skilled labor and difficulty attracting young people to the field make automated machine tending attractive, especially for shops aiming to increase spindle utilization and run lights-out overnight while not staffed. Robots also can help attract prospective new hires interested in more than simply loading and unloading machines all shift long.

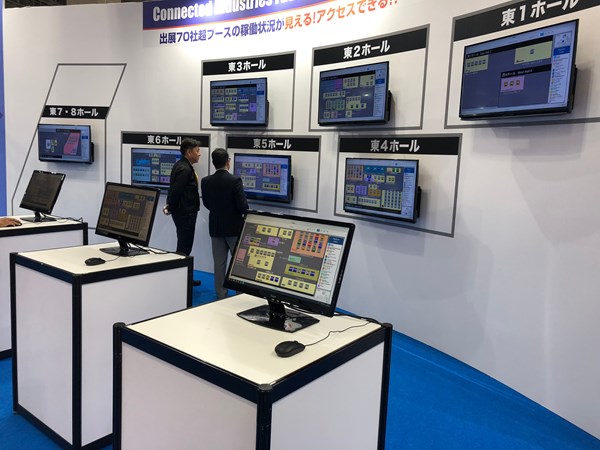

Robots were particularly conspicuous at this past November’s Japan International Machine Tool Fair (JIMTOF), which was the 29th edition of the biennial show organized by the Japan Machine Tool Builders’ Association and took place at the Tokyo Big Sight convention center. Like the International Manufacturing Technology Show (IMTS) this past September in Chicago, Illinois, JIMTOF 2018 beat previous records for visitor attendance (more than 153,000 this year) and number of exhibitors (1,085). Industry interest in such trade shows certainly is not waning as manufacturers continue to visit to learn how shopfloor strategies such as automation can increase their businesses’ efficiency and spur growth.

Expectations, Evolution Examples

Here are three expectations I believe shops now have about robots. These points are illustrated with examples I saw at the show of how the technology has evolved with respect to each expectation:

1. Robots should be able to operate safely alongside people.

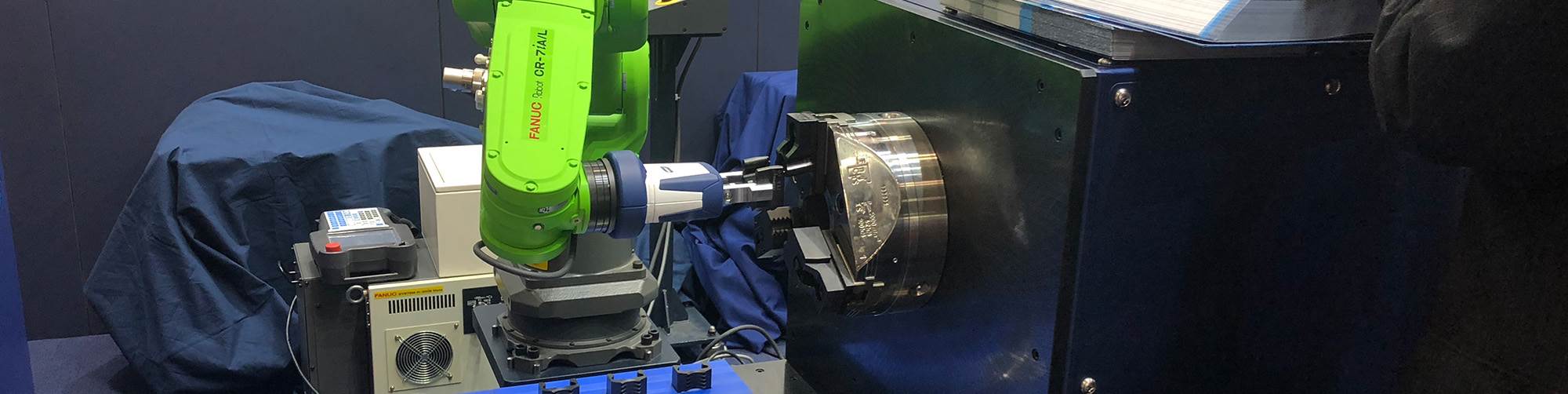

Manufacturers continue to need conventional robots with safety guarding to prevent people from entering the robots’ work area, especially when applications call for high speed or payload capacity. At JIMTOF, however, there were just as many (if not more) collaborative robots or “cobots” on display.

Cobots use sensor technology to avoid harming people in the same work area. In some cases, sensors are integrated into the robot itself to stop its motion when it unexpectedly contacts an object or person. Other applications use sensors to slow or stop robot motion depending on a person’s proximity to the work area.

When cobots were new to the automation scene, the existing ISO 10218 standards for industrial robot safety requirements (published in 2011) did not adequately address their safe integration into a manufacturing facility. This prompted the automation community to develop the ISO/TS 15066 technical specification. One important aspect of this is that it provides robot integrators and manufacturing personnel guidance about conducting more sophisticated, preliminary risk assessments of both the cobot and the environment it will share with humans.

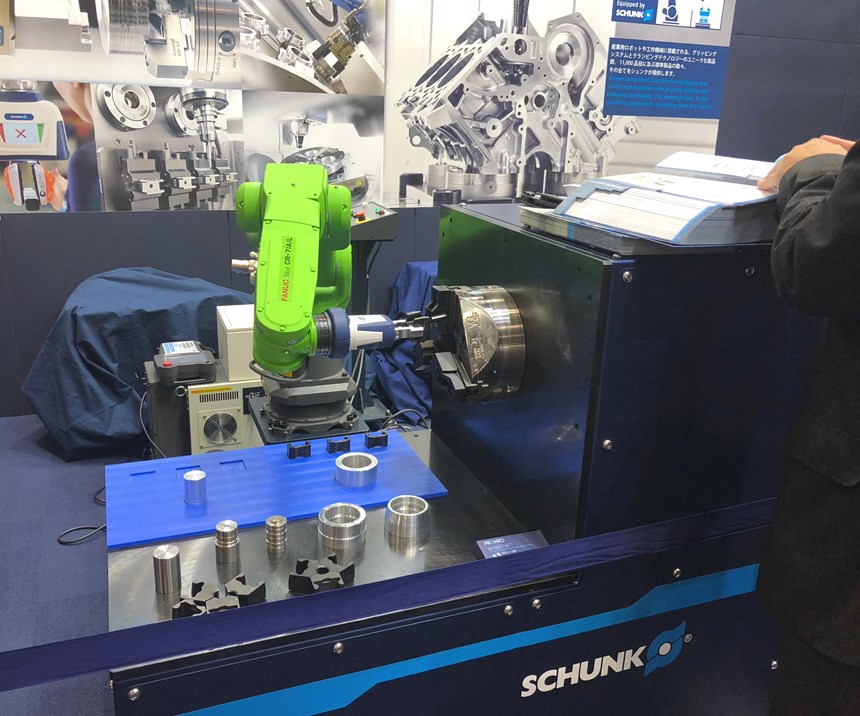

Another sign that cobot interest is increasing is the development of end effectors designed specifically for them. One example at the show was Schunk’s Co-act gripper, which features a soft cover and lacks sharp corners and pinch points. Gripping force is also less than 140 Newtons (per ISO/TS 15066) to prevent injury.

2. Robots should be able to be redeployed to multiple machines in a facility.

Job and contract shops that machine a high mix of parts in low volumes can benefit from robotic loading just as high-production operations can. Moveable, self-contained loading units with robot and parts collection systems can facilitate this. Once the job is completed on one machine, the unit can be easily moved to another with a pallet jack or forklift. Leveling pads align these units with the machine. Some units work with various machine tool controls, and do not require the machine tool builder to supply a special robot interface. Instead, a programmable logic controller (PLC) is all that is needed to connect the machine and loader.

A few machine tool builders at JIMTOF took this a step further by integrating cobots with automated guided vehicles (AGVs) that can move autonomously from machine to machine. The AGVs use sensor technology to safely guide them throughout a facility without bumping into equipment or people as they are redeployed to other equipment.

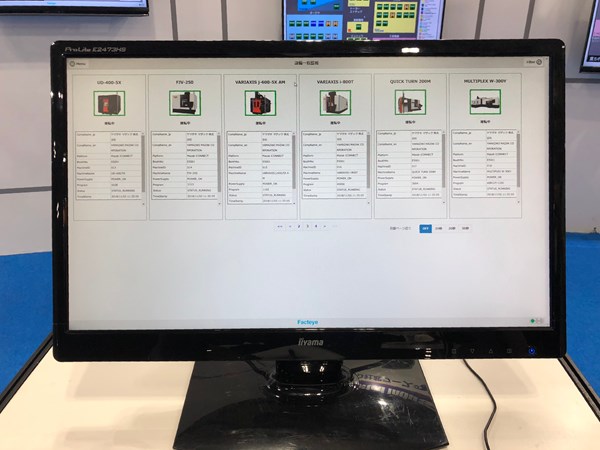

3. Robots should be easy to integrate.

The example above describes how easy it can be to integrate a robot with a machine tool. However, the extent to which this is the case was demonstrated most clearly at machine tool builder booths with no robots on display at all. The message is not that robots are not important or valuable, but that integration is so easy that machine tool builders do not consider robots to be a necessary part of a booth display.

That said, some machine tools have built-in robotic automation so an integrator is not needed. For example, Murata showcased twin-spindle chucker lathes with integrated gantry loaders. In fact, the company now offers carbon fiber gantry loaders that are said to move 50 percent faster than standard loaders.

In addition, Okuma introduced an LB3000 EX CNC lathe with Armroid, an articulating robot loader mounted in the machine’s work area for part loading/unloading. The robot operating system does not require teach-in during new job setups, and it can perform collision-free movement while machining on a part is being performed. The robot can store three different end effectors and change over as needed according to the application. Like the previous example, integrating the robot into the machine conserves floor space.

Related Content

3 Considerations for Revising Design for Manufacturing Efforts

When revising part designs, investigate the 3D CAD, the 2D drawing and the part’s functional requirements to determine which details should be tightened up.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read More6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

Read More4 Manufacturing Trends That Cannot Be Ignored

The next five years will present their own unique set of challenges, and shops can alleviate them by embracing these technologies and trends.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More