Video: Applying “Dengeln” for Finishing Turbine Blades

This alternative to grinding, polishing and shot peening enables turbine blades to be machined and polished in one setup.

Share

You might know “dengeln” to be a peening method of smoothing and sharpening the blades of scythes or sickles via manual hammering. Starrag says it has developed on-machine dengeln technology that uses an electrically powered tool to finish turbine blades after machining to a roughness value of just 0.2 micron Ra.

The process uses a tungsten tool with a spherical tip pulsed to 600 Hz that repeatedly impacts the blade surface and changes the original structures of surface boundary layers to a depth of 10 mm. This capability offers the possibility to eliminate secondary polishing, grinding and shot peening to finish blades. It can also eliminate manual polishing for dies and molds.

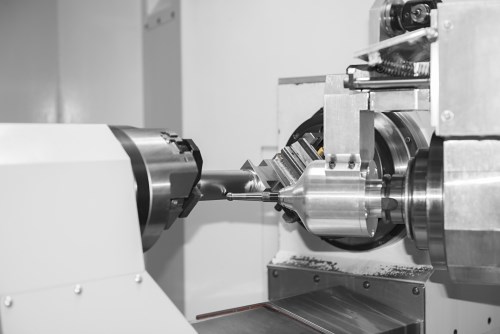

The video above shows one of the company’s five-axis LX 051 machines performing the dengeln process to finish a typical turbine blade after machining.