Workforce Development at a Small Shop, Big Shop

Learn about the tactics a small shop and a large one use to develop and retain their employees.

Share

At this year’s inaugural Top Shops Conference, I moderated a workforce development panel consisting of a diverse group of people. Two of them were Mike Griffith and Reid Leland. Both men face the same problems of growing and retaining new employees, but the difference in scale of their shops means their approaches are a bit different.

- Mr. Griffith, chief operating officer of 400-employee Major Tool and Machine in Indianapolis, Indiana, highlights the shop’s efforts in employee development, care and engagement.

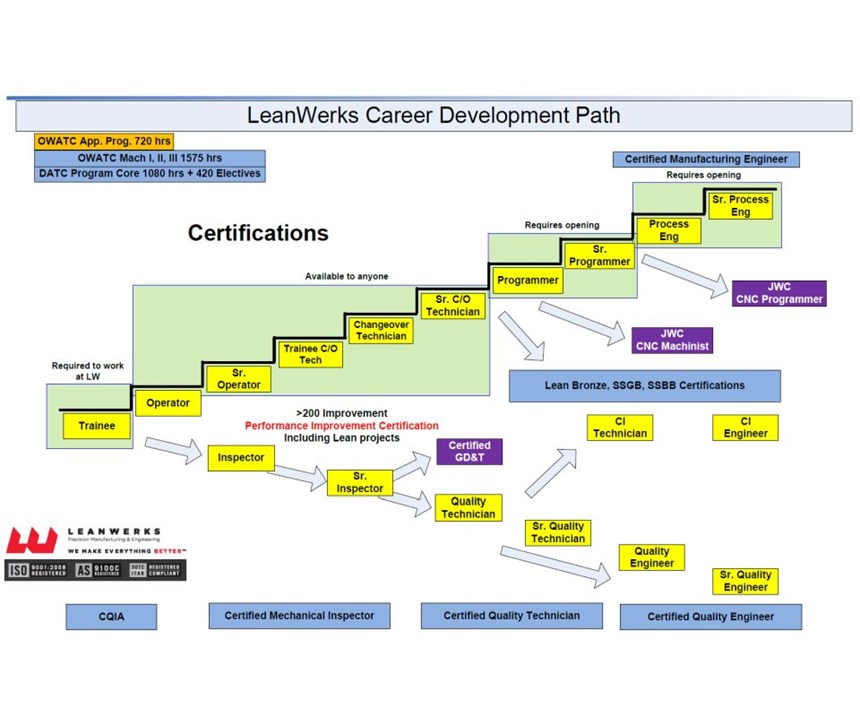

- Mr. Leland, president of 30-person LeanWerks, located in Ogden, Utah, describes some his shop’s worforce development tactics that largely required a bigger investment in time rather than money.

Related Content

-

How I Made It: Montez King

From high schooler pushing a broom on a shop floor to executive director of the National Institute of Metalworking Standards (NIMS), a series of bold decisions have shaped Montez King’s career path.

-

How I Made It: Nushrat Ahmed: CNC Swiss Operator

By day, 21-year-old Nushrat Ahmed is a CNC Swiss operator making automotive parts. By night, she handcrafts crocheted items.

-

How I Made It: Trevor Hirschi, Instructor, Bridgerland Technical College

Student, operator, instructor, shop owner — Trevor Hirschi’s many roles have enabled him to understand both the technical and creative sides of manufacturing.