Workholding, ESOPs and AMRs: Building Midwest Job Shop Success

A to Z Machine’s True North mission statement defines an aim to become the best employer and supplier in the region. But what policies and technologies support this mission? From AMRs to Zero Point clamping, find out below.

Share

Appleton, Wisconsin-based shop A to Z Machine first caught our attention through its ESOP and thriving apprenticeship program, becoming our 2022 Top Shops Honoree in Human Resources. When I visited the shop in the summer of 2022, it was also solidifying its updated mission statement and accompanying culture shift, plus installing a double-column bridge mill and getting comfortable with an AMR. Three years later, these efforts have borne fruit into success and are joined by several new initiatives meant to make the shop both a more valuable partner to its customers and a healthier work environment for employees.

A to Z uses its FANUC CNC Simulator to train new hires and apprentices, giving them experience behind the controls of a machine without the risk of crashing a machine. Photo courtesy of A to Z Machine.

True North – Employer of Choice

Marc Manteufel, manufacturing engineering manager at A to Z, says the company’s “True North” mission statement consists of two parts: becoming the regional employer of choice and becoming the supplier of choice across its markets. Over the past three years, the shop has taken steps to meet both goals.

First among its steps to become the regional employer of choice was to focus on the culture at the shop. Management now regularly holds monthly meetings open to all employees where they can ask questions about strategy and company performance. Manteufel says that attendance at these meetings began to grow toward the end of 2024 and the start of 2025 and theorizes that this growth in interest is largely due to the maturation of the company’s employee stock ownership plan (ESOP). The common misconceptions about the program, including that employee ownership meant the company now saw a flat organization structure or that every employee needed to be involved in every decision, were largely corrected by 2022. But after accumulating stock for three additional years, a growing share of employees feel invested in the direction of the company and want to be able to bring concerns and questions to leadership to ensure the health of that stock. Manteufel also says the leadership team is continually working to consult employees on matters that relate to them and where their input would be helpful.

A to Z Machine has also increased its investment in recruitment over the last few years. With the retirement of several technical education teachers at local schools, their less experienced successors have reached out to shops like A to Z for assistance. In addition to helping these schools, the company and several of its competitors now serve on advisory committees for Fox Valley Technical College and the Northeast Wisconsin Technical College’s manufacturing programs, helping the schools adapt their programs for modern manufacturing needs. A to Z has also built a relationship with Cooperative Education Service Agency 6 (CESA 6), a state-funded entity helping act as a liaison between job shops and schools, in part by setting up field trips to A to Z and coordinating career fairs. The shop has also hired a full-time talent acquisition specialist to assist with training and development, recruitment and community outreach.

This increase in talent investment also carries over to the shop floor. The shop is building out “A to Z University,” a custom training software embedded in the company’s HCM platform. The overall platform handles payroll and tracks certifications, deadlines, estimated completion dates and job status, with training soon to add another pillar to the platform. Manteufel says that there is a lot of development left on the software, but it is just starting to roll out to employees in its current form. Once it’s complete, the platform is meant to have a full library of videos and presentations so that employees can upskill on machines and software, as well as developmental pathways that show employees the skills they need to master for a promotion (and which classes can get them there).

True North – Supplier of Choice

For improving A to Z’s status as a top supplier of choice, Manteufel says the shop has sent questionnaires to and sat down with customers to learn more about what they value from a supplier, using their answers to guide its priorities for growth. Having this information also helps convince employees on the shopfloor of the necessity of any changes — especially with the ESOP meaning that employees share in the benefits of additional business. So far, Manteufel says the shop has improved on-time delivery rates and lowered lead times, with work planned to increase quality and further improve on-time delivery.

Part of these improvements come from the updates A to Z was implementing at the time of my first visit. While that visit focused on the building dedicated to job shop work, the company also maintains another building across the street for production jobs. These are still largely low-mix, high-volume, but Manteufel says the increased consistency in jobs requires a difference in mindset from highly adaptable job shop work, as well as different gaging and inspection equipment. In the past few years, it has also built out 30,000-square feet addition to the production facility, where A to Z has already set up nine additional CNC machines.

For its part, the job shop building has seen the full implementation of its double-column DN Solutions bridge mill. The shop has an indexing head and a right-angle head for the 3+2-axis machine, a combination which allows the shop to tackle compound angles and machine features that previously would have been impossible or required difficult set-ups on a boring mill. Manteufel says it has worked well for the shop in heavy-duty five-axis work and roughing, though its lower speed compared to the shop’s less powerful bridge mills means that simpler work (especially three-axis work) goes to these other mills. Manteufel notes that the shop has taken on so much heavy-duty five-axis work in the last few years that the shop will soon need an additional bridge mill to prevent potential bottlenecks, possibly replacing one of the older bridge mills.

TED not only works for A to Z delivering tools, but the AMR has also become a sort of mascot for the shop. Manteufel says TED regularly features on A to Z’s social media page. Photo from Evan Doran, Modern Machine Shop.

TED Does Everything But Talk

Automation has also helped reduce the shop’s lead times. A to Z only uses one Halter machine-tending robot in its job shop area, but makes good use of its Mazak multi-pallet Palletec systems and a DN Solutions multi-pallet system for queuing work. More uncommon, however, is TED.

TED, short for “tools efficiently delivered,” is an autonomous mobile robot (AMR) the toolroom uses to deliver tools to stations across the shop floor. A to Z had already started to use TED by the time of my initial visit, but with every passing year, the team has added more locations to TED’s database as new machines arrive on the shop floor or employees present the potential efficiency savings or time savings of a new delivery point.

From February 2024 to February 2025, Manteufel says TED averaged about 10 miles per week delivering tools, as the robot fills about 65 tool list requests and 50 gage list requests each week. He also says that the few hardware glitches the team has experienced with TED have been easily solved, and the AMR has provided enough benefit to the shop that Manteufel says it’s only a matter of time until A to Z adds more. He sees use cases for an AMR performing similar work to TED at the production facility, as well as potentially delivering parts to inspection or transporting parts in the shop’s warehouse.

Simulation On and Off the Machine

A newer tool in A to Z’s belt is its FANUC CNC Simulator. Manteufel first saw the simulator at BI-MU 2022, then encountered it again with other members of the A to Z team during a tour of a technical college. This device runs a virtual model of a machine based on operator G code, with realistic cutting (and crashing) sounds. Manteufel immediately saw the use for training apprentices and new hires at A to Z, as it comes “as close to real life as you can get without being on the $500,000 machine tool, with the safety and financial worries of the real world.” He creates blueprints for training parts that trainees will then program in GibbsCAM and “machine” through the FANUC simulator.

GibbsCAM is the shop’s CAM software and performs its simulations, with programmers importing workholding solid models for better accuracy. For training, mentors tutor their mentees on GibbsCAM, then supervise their mentee’s toolpath creation through the software. The resulting G code goes into the GibbsCAM simulator, and then on to the FANUC machine simulator, where the mentee learns how to import G code onto a machine and input work and tool offsets. There, while the mentee oversees the machine, the mentor will give their student challenges, requiring the mentee to make further offset adjustments to avoid crashing.

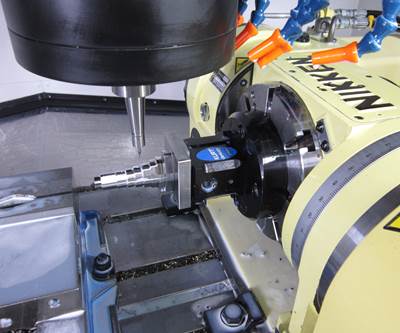

Closing the machine door on the VMCs equipped with the Lyndex-Nikken Zero Point system requires operators to unplug and remove the airline from the machine. As the system automatically clamps when disconnected from an airline, this ensures parts will always be secure when machining starts, something that was not always the case with manual clamping. Photo courtesy of A to Z Machine.

Every Reason For Zero Point

Manteufel drew attention to one particular job where the shop improved both setup times (benefitting the customer) and ergonomics (benefitting the employees). The job in question was a long-running project the shop had already been producing for seven years, involving 64-inch by 20-inch fixture plates that held a large austempered ductile iron casting. The job would run on two vertical machines for two shifts a week, every week — high-production by A to Z’s standards. Each machine had two fixtures for the job, so shopfloor staff would have one fixture and plate running in each machine while they prepped the machine’s other fixture and plate.

After seven years, the fixturing was starting to wear, and Manteufel wanted to make refinements to the fixture, including redesigning how the fixture plate clamps inside the machine. After consulting distributors and manufacturing representatives, he heard that Lyndex-Nikken planned to begin distributing its Zero Point clamping system in the U.S. Manteufel did further research into the system, then bought $26,000 of Zero Point equipment just before IMTS 2024 and took delivery at the show, implementing the system by November.

Manteufel describes this system as a pneumatic system made of a fixture and a receiver puck with a pull stud. The stud goes into the fixture and gets located, then is clamped at the same time. The natural state of the fixture is to clamp the puck above it, with an active airline connection necessary to unclamp parts — though as part of that requirement, operators do not need to manually tighten or loosen bolts and pins at any point. Not only does this solve errors where an operator may have forgotten to clamp a part, this also provides ergonomic benefits for operators. The old fixture was 20 inches wide, while the part was 12 inches tall, requiring operators to reach in and over every hour for every part. Manteufel says that fatigue and injury were constant worries when using this older system, but these fears are nigh-nonexistent now.

The Zero Point system also stood out to Manteufel for the connection itself. The system has a segmented collet with rubber between each segment to ensure full contact, whereas Manteufel says most systems would use either a few locking pins or locking ball bearings. The latter two designs include much more space for dirt and debris to enter and wear the system, while the full-contact Zero Point system avoids this issue.

This system shows better cutting performance, Manteufel says, crediting this to tighter clamping. This also reduces chatter and has led to an increase in tool life on account of fewer tool failures. It has also cut part-to-part time by just over half, improving uptime on this job. Manteufel calculates that the ROI for this equipment is just under half a year for his use case, and now that he knows how to use it, he can also bring its strengths to future applications to improve set up changes.

It's these kinds of advancements that help A to Z Machine reach its True North. Systems like the FANUC simulator and the Lyndex-Nikken Zero Point clamping reduce the risk of errors and make the role of shopfloor employees safer. Technologies like TED, the large-format bridge mills and the Lyndex-Nikken Zero Point clamping (again) help the shop delivering parts to clients ever faster and more efficiently. And even older changes like the ESOP prove more powerful each year as the staff grows more motivated and makes True North not just management’s goal, but their own.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Top Shop Builds Upon Employee Ownership for Future Success

In its quest to become the Fox Valley’s best-in-class employer, A to Z Machine has adopted an ESOP, expanded benefits and invested in apprenticeships.

Read MoreShop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More