HMC Skiving Consolidates Gear Machining

A rigid machine platform and the right CNC promise to reduce stackup error and cycle times for both established gear-making operations and new players.

Gear manufacturing is less exclusive than it used to be. That is according to a machine tool builder offering what are said to be the first horizontal machining centers in the world capable of power-skiving, a demanding tooth-shaping process in which the workpiece and tool rotate in constant contact and near-perfect synchronicity at a precisely defined angle of engagement. Combined with a horizontal configuration’s well-documented potential for setup reduction, skiving capability reportedly enables machining gears mostly complete in a single setup. Manufacturers that stand to gain include not just established, high-production gear makers, but also any operation interested in machining high-quality gears without lengthy lines of dedicated equipment.

Originating from the same organization that spawned Toyota Motor Corp., JTEKT Toyoda Americas has deep roots in manufacturing machinery geared toward automotive components. On GS series power-skiving HMCs, this legacy is exemplified by a control unit that, until this point, has been restricted to machines dedicated to camshaft and crankshaft grinding. “We took one proven technology and married it to another proven technology,” says William Terry, product manager, about the combination of a rigid HMC platform and the high-speed spindle synchronization capability of the GC70 CNC.

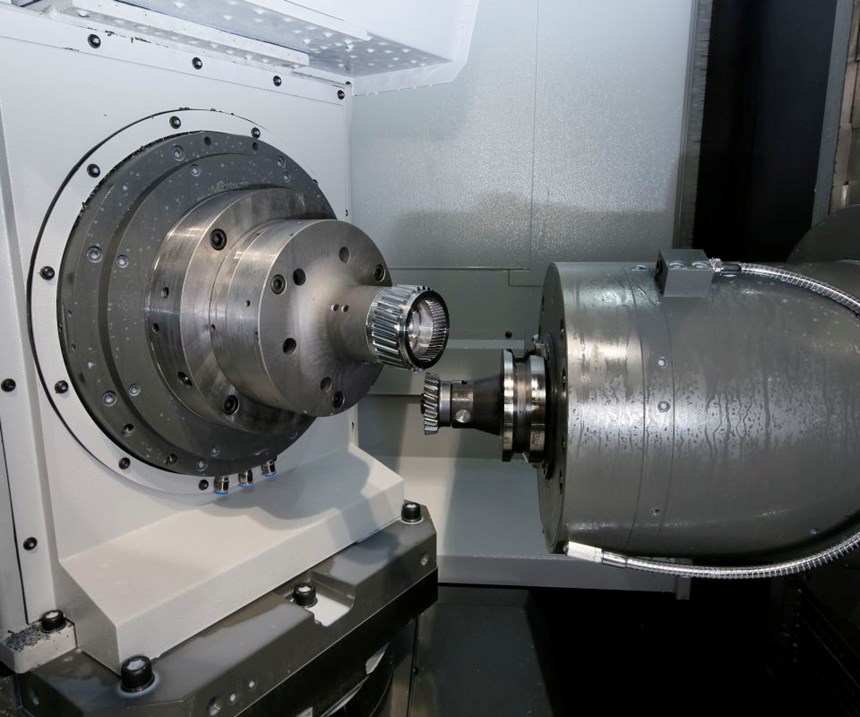

Rather than a tombstone or other fixturing, GS series HMCs feature a workholding spindle that indexes 270 degrees to achieve the proper cross-angle between the skiving tool and workpiece. This indexing spindle also improves part access for other tooling in the machine’s 40-position automatic toolchanger, including end mills, drills, grooving tools and even single-point tools for turning symmetrically round features by manipulating both spindles. By consolidating production lines that often consist of 10 pieces or more of dedicated machinery, this machine configuration can enable manufacturers to locate critical part features with high precision, whether in relation to one another or to any other critical datums. “We can cut at least five machines out of most processes,” Mr. Terry says. In fact, a single clamping can take a gear through turning, internal and external skiving, milling or drilling around the periphery, and even chamfering and deburring processes that might otherwise require specialized equipment. “That means zero stackup error,” he continues. “Every feature, every dimension, every tolerance—they’re all dead concentric to each other.”

As for precision, testing demonstrates the machines can reliably and repeatedly produce gears to American Gear Manufacturers Association (AGMA) quality standards of Q11. However, that’s not a hard limit, he says, explaining that users in the field must find their own balance between quality and productivity. “If you need that AGMA 14 or 15 spec on every part, and you don’t want to waste time in the roughing process, maybe you can just plow through to get the part off the machine and onto a grinder. Or, if you have some tool life and cycle time to burn, you can have finished gears when they come off the machine.”

Whatever the user’s requirements, effective skiving begins with rigidity. Constant contact across wide swaths of the multi-toothed tool and the work creates “tremendous force,” he says. Even if that weren’t the case, two rapidly spinning, coordinated spindles would leave little room for deviation from the skiving tool’s specified crossing angle and feed rate. Even slight chatter can be sufficient to throw geometry out of specification.

To avoid chatter, “you want everything that’s holding that part to be cased in stone, or in this case, iron,” Mr. Terry says, referencing the cast iron construction common to all the company’s HMCs. Like the FH-J models on which they’re based, GS series HMCs feature double rows of ceramic bearings at the front and back of the spindle and oversized roller bearings on all axes. In fact, aside from the workholding spindle and lack of a pallet system option, the most significant differences between GS series machines and their FH-J series cousins are glass scales and higher-quality axis drives.

Capability to synchronize two rapidly rotating spindles is largely the province of the GC70 CNC, as well as the machine’s Toyopuc programmable logic controller. “The main thing is the processing speed—the ability to control multiple axes in a full synchronous environment,” he says about the combination of these systems. “We’re waiting for the material to be removed; we’re not waiting for the electronics to catch up to the physics.”

He adds that fast processing speed is important to ensure not just proper synchronization, but synchronization at speeds that make HMC skiving cost-effective. For its part, the GS series offers work rotation as fast as 3,000 rpm and tool rotation as fast as 6,000 rpm. Mr. Terry emphasizes that this is fast enough to justify the use of carbide tooling rather than high speed steel. This provides the flexibility to not just consolidate operations, but to choose the balance between gear quality and production speed. Longer-lasting carbide tools, he explains, can spend more time in the cut at slower feed rates in order to impart smoother surface finishes. In contrast, HSS might require more aggressive feeds that avoid burning up the tool but leave a comparatively rougher finish.

The CNC also features a conversational programming interface specifically (and only) for the skiving function. Through a series of queries about angles and geometries, this system prompts the user to enter enough information to virtually define any spline or helical or straight gear (beveled gears, hypoid gears and worm gears require other processing options). In addition to the flexibility of an HMC, avoiding the need to purchase dedicated software can potentially make it easier for virtually any operation to take control of its own gear manufacturing. “The machine is geared for high volumes, but it’s still a great fit for a job shop,” Mr. Terry says.

Related Content

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)