Share

5G’s potential for real-time chatter control has already been demonstrated in blisk milling. Other applications might include preventive maintenance, facilitating augmented/virtual reality, and ensuring a “digital twin” matches its real-world counterpart throughout a manufacturing process. Photo: Ericsson

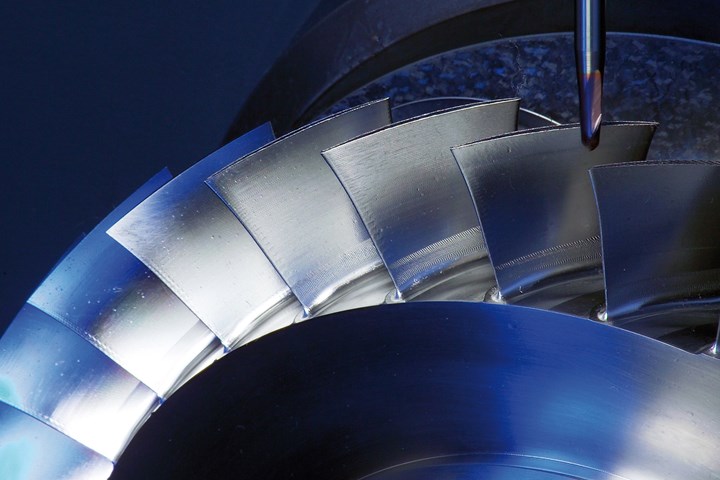

On the rare occasion when friends or family members become interested in the specifics of what I write about, blisk-milling videos are an easy go-to. There are few better ways to gain an appreciation for modern machining technology and skilled CNC programming than watching five axes maneuver in concert through the twists and turns of these fan-like turbine components.

Like many of the shop owners and managers I visit, these friends and family members might be surprised to learn that there is a direct link between this process and the technology driving the latest smartphones. Fifth-generation (5G) wireless technology is here, and it provides sufficient speed for data feedback loops between CNCs and workzone-mounted sensors to compensate for machining vibration in near real time.

5G’s potential for controlling blisk-milling chatter — a progressive, self-perpetuating form of vibration familiar to any machinist — has already been demonstrated (including at GF Machining Solutions’ IMTS 2018 booth). As 5G spreads, it stands to reason that manufacturers could apply the same concept to monitor and control all manner of machining process variations.

Research into 5G-augmented blisk machining originated in Europe with a partnership between the Fraunhofer Institute for Production Technology, a German research organization, and 5G infrastructure developer Ericsson, a multinational telecommunications firm based in Stockholm, Sweden. Ericsson documentation on the project provides good reason for targeting these flight- and safety-critical components: The blisk-milling process is not only in high demand, but also demanding by nature, and demanding processes are expensive.

Impressive as they may be, blisk-milling videos do not convey the fact that, according to Ericsson and Fraunhofer, these components spend as long as 20 hours in a five-axis machining center. Nor do viewers get any indication that one in four requires rework after all that milling. In fact, machining accounts for half of a blisk’s average overall production cost. To make matters worse, blade designs are trending thinner, more flexible and more difficult to machine. Researchers say 5G-enabled chatter control can help by reducing blisk machining rework rates by 10 percent.

The 5G-enabled control loop begins at the blisk. A small accelerometer (vibration sensor) glued to the part communicates with the CNC via a transmission device, which is also attached to the part. Based on this data feed, the CNC calculates and issues a stream of corrections to damp vibration (for example, a spindle speed adjustment). 5G connection speed ensures these corrections can be made before the physics catch up — that is, before worsening vibration makes an adjustment obsolete.

More specifically, 5G networks can provide latency (the transmission delay from sensor to CNC) approaching one millisecond. In addition to lower latency, they offer higher bandwidth (how much data can be moved at once). Essentially, lower latency makes the data “pipeline” faster, while higher bandwidth makes the pipeline wider. In short, 5G moves more data faster. The source of the connection in an industrial facility is likely to be an easy-to-install, industrial-grade system like Ericsson’s Industry Connect. Just as they would for a private 4G network, users simply plug in the industrial-grade transmission unit and install roof-mounted antennas to spread wireless coverage throughout the facility.

As industrial 5G becomes commercially feasible, it is easy to envision how virtually eliminating data-transmission lag could facilitate monitoring and control beyond the machining process itself. Examples might include real-time monitoring for preventive maintenance; using augmented and/or virtual reality devices for tasks like training or assembly; or ensuring a consistently perfect match between a part and it’s “digital twin” during operations conducted in different facilities. Access to more data more quickly facilitates deeper data analysis, particularly analysis driven by artificial intelligence. Robots can leverage the speed of 5G for seamless access to cloud-based intelligence as well as greater agility and responsiveness.

5G offers more than just speed. Another advantage is capability to support far more interconnected devices, from automation systems to machine tool sensors to shopfloor tablets and other assets, on one network. Additionally, bandwidth and latency can be allocated as needed. Among other benefits, this avoids the risk of interference with critical feedback loops like the one employed for chatter control during blisk milling. Reportedly more stable than Wi-Fi and other wireless solutions, 5G could eliminate the miles of expensive cabling that populate modern factories.

Amid discussions of autonomous vehicles, movie downloads in seconds and other applications that have yet to become reality, it can be easy to get lost in all the hype about 5G. The blisk-milling research proves a direct and potentially massive impact on not just the manufacturing industry, but CNC machining businesses specifically. Shop managers would be wise to educate themselves.

Related Content

Precision Shop Adopts Machine Monitoring, Boosts Revenue

Adopting machine monitoring helped LeClaire Manufacturing boost its vertical CNC utilization rates 38 percentage points and gain millions in revenue.

Read MoreEasy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreAerospace Shop Thrives with Five-Axis, AI and a New ERP

Within three years, MSP Manufacturing has grown from only having three-axis mills to being five-axis capable with cobots, AI-powered programming and an overhauled ERP. What kind of benefits do these capabilities bring? Find out in our coverage of MSP Manufacturing.

Read MoreLeveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

Read MoreRead Next

Breaking SPC Limitations Without Breaking Rules

Machine learning helps prove the merit of statistical analysis techniques that do not require plotting CNC machining quality data on a bell curve.

Read MoreData-Driven Manufacturing Scales Down

An automatic gaging station demonstrates the potential of shopfloor connectivity at the level of the individual machine tool.

Read More3 Principles for Growing with Machine Monitoring Data

Following a few basic principles can help shops get a return on their machine monitoring systems without losing faith first.

Read More