Why Use Solid-State Additive Manufacturing?

New opportunities are coming thanks to 3D printing processes where the metal doesn't melt.

Share

Most metal additive manufacturing (AM) methods involve sintering powder with an energy source like a laser or an electron beam, or a welding-like process that melts powder or wire to build up parts. While these methods are suitable for all sorts of applications from medical implants to structural aerospace parts, the need to melt and resolidify the metal creates stresses. That stress can cause metal parts to deform, break free from their support structures or even warp the build platform.

The heating and subsequent cooling that happens with directed energy deposition and other processes based on melting metal can generate enough stress to bend a build plate. Photo: Matthew Pantano, Sciaky Inc.

In a solid-state AM process, the material doesn’t melt. Instead, metal is built up using other mechanisms like friction, pressure and velocity. Common types of solid-state AM include friction stir welding, cold spray and sheet lamination. There’s even a method powered by compressed shop air. These processes involve little to no heat, which means little to no residual stress created in the part.

But there are other reasons to use solid-state AM on top of that stress-free advantage. Here are just a few that we’ve covered over at Additive Manufacturing:

To blend a variety of materials.

Meld’s 3D printing process is based on friction stir welding applied within a machine tool. The technique uses friction and pressure to transform solid metal stock into final parts without melting. That beginning stock can be metal powder, solid bar or even chips from machining.

The combination of a stress-free process and flexible material choice provides an interesting opportunity: the chance to blend dissimilar metals. A Meld machine can be configured to easily switch between different feedstock, allowing users to alternate materials and create combinations that would not be possible otherwise.

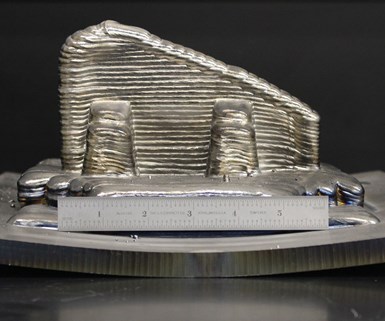

The solid-state nature of friction stir welding enables Meld to build parts of various materials and feedstocks. Metal is plasticized and applied without heat.

To connect existing parts to the Internet of Things (IoT).

One unique advantage of a solid-state process is that the technique makes it possible to embed electronics in otherwise solid metal parts. Tri-D Dynamics is taking advantage of this concept with its robot-driven 3D printing process based on cold spray.

The company’s hope is not necessarily to build complete parts using cold spray. Instead, the founders see opportunities to use this process in combination with machining. A electronic device could be added to a milled slot, for instance, and then encased using cold spray. The technique could be a useful way to add sensors and IoT connectivity to down-hole oil extraction equipment and other items used in harsh environments.

To build brand new smart devices.

Fabrisonic is pursuing an aim similar to Tri-D Dynamics, using an entirely different process: ultrasonic additive manufacturing (UAM). This method is a type of sheet lamination involving thin sheets or coils of metal foil that are vibrated together with an ultrasonic welder. The vibrations remove the oxide layer from the metal sheets, allowing them to bond together at temperatures less than 200°F.

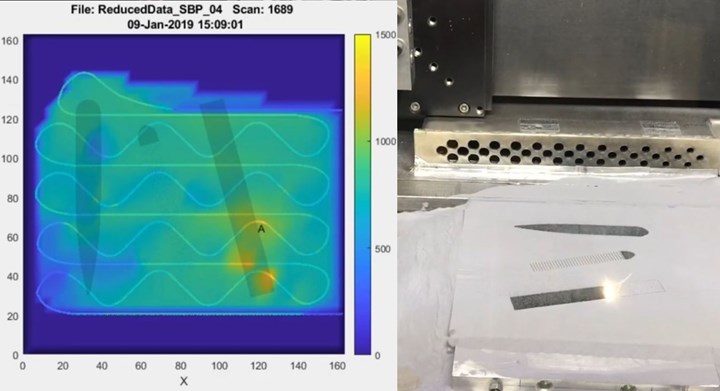

Fabrisonic’s UAM process can be used to build internal channels, embed motors, and combine aluminum and copper within the same part. The company has even developed a “smart” build plate for powder-bed fusion metal 3D printing. An embedded fiber-optic sensor running within the plate allows users to track the temperature, strain and, yes, even the stress within the build. Solid-state additive manufacturing could just be the next advance for AM processes based on melting.

The fiber-optic sensor embedded via UAM allows the “smart” build plate to capture data like temperature spikes during the powder-bed fusion printing process. Images: Fabrisonic

Related Content

OEMs Showcase Hybrid Manufacturing Applications

Mazak and Mastercam worked together to demonstrate the viability of hybrid additive/subtractive machining techniques at a recent event held in Florence, Kentucky.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Additive Manufacturing with Sheet Lamination

No longer limited to paper, sheet lamination bonds sheets of material together to form an object. Companies are exploring the possibilities of this process.

Read MoreCan You 3D Print with Machining Chips?

Meld Manufacturing’s solid-state metal 3D printing process is compatible with a range of materials and formats, even chips from machining.

Read MoreWhy Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)