Nine out of 10 times a standard dial or digital indicator will fulfill any gaging requirement. Typically, it is not a problem to mount a dial indicator to a bench-height stand or portable gage. There is plenty of room all around the gage for the dial indicator to be in sight and free from obstructions. However, given the way a special gage needs to be used, the normal orientation of a standard indicator occasionally is not right for proper viewing by the user. There might also be limiting restrictions in the way the gage needs to be positioned, which can cause a normal indicator to not physically fit into the gaging location. In this case, the compactness of a perpendicular indicator might be required.

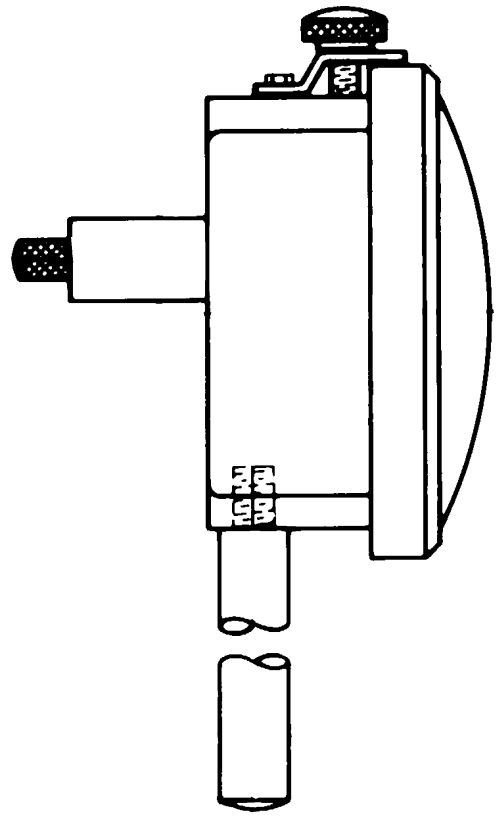

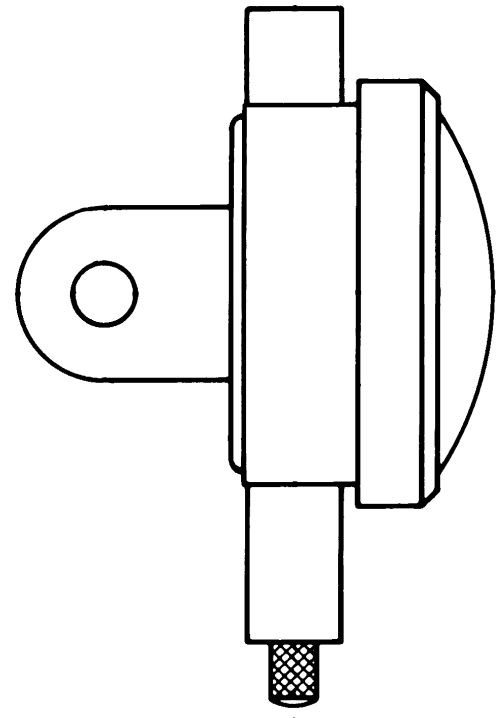

A dial indicator is normally configured in such a way that the face is in line with the stem. This configuration eases upright mounting, but it can also occupy an increased amount of space or provide an incorrect viewing angle for the user. The perpendicular indicator was devised to overcome some of these application issues. Its name says it all. The indicator’s dial face is perpendicular to the travel of the spindle, so in effect, the spindle is in line with the user’s line of sight. A dial indicator is typically configured so that the sensitive contact is in line with the face of the indicator. Typically, an upward movement of the contact represents a larger value on the face of the indicator. With a perpendicular indicator, the sensitive contact is at a right angle to the face of the indicator, and an inward movement of the contact toward the face of the indicator represents a positive value.

A typical mechanical perpendicular indicator will have a post or bar mount in the same orientation as the stem on the indicator. This enables the indicator to be mounted on a machine lathe, for example, with the sensitive contact on the part and the face of the indicator in plain view for the setup person to align the part with the spindle.

Perpendicular dial indicators are made from racks, pinions and gears like typical mechanical indicators, only the typical line movement needs to be bent 90 degrees. To do this, a special spiral gear or a partial gear segment can be employed to change the direction of the movement. It’s pretty much precision mechanics, but it can be challenging with high-magnification indicators in which a second set of gears is needed to achieve the magnification.

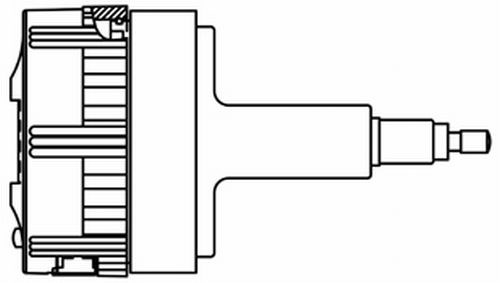

Digital indicators are a little different. Most digital indicators incorporate long-range scales. Trying to attach a large digital display perpendicular to the end of this scale makes for a very long and awkward-looking device—not a very good combination for a robust, portable gage.

With the short-range digital indicators commonly seen on comparative-style gages, the transducer is a stand-alone item. It can be moved out of its standard case and mounted in a special back on the rear of the normal display. Thus, the indicator looks and acts like it always does, but the transducer is now perpendicular to the back in a compact package.

With this type of mounting arrangement, there are many more options for displaying the gaging results in tight places. Perpendicular indicators can be used in deep blind holes where the gage is dropped into the hole and the operator reads the measurement result from the top of the hole. Or, in the case of a gear gage, it is important to measure the part while still mounted in the machine. By applying a perpendicular digital comparator to the existing mounting, the operator can clearly see the size and make the appropriate decision.

One final note: the April print issue marks the 20th anniversary of the Quality Gaging Tips column. That is perhaps not such a milestone in the greater scheme of things, but it has given me a very good perspective on the topic of dimensional gaging as a whole. While most of the things we talk about here are tactical, problem-solving matters, it is also clear that there are some larger trends driving the process. We’ll be discussing those in a special “Trends in Dimensional Gaging” feature in next month’s issue. I hope you check it out.

.png;maxWidth=300;quality=90)