Ceratizit Launches Sustainability Strategy to Reduce Environmental Impact

The company aims to be carbon neutral by 2025 and achieve net-zero emissions by 2040, among other sustainability goals.

Share

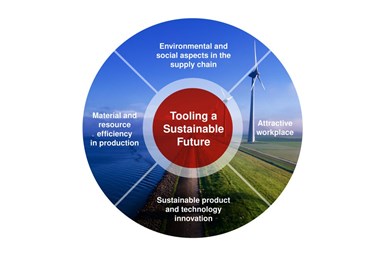

Ceratizit USA Inc. presented its sustainability strategy during AMB 2022 in Stuttgart, Germany. The company aims to solidify its leadership in sustainability for the hard metal and cutting tool industry by 2025. In a Ceratizit press conference, executive board member Thierry Wolter announced the company’s sustainability goals, which will reportedly affect and change the entire supply chain.

To become sustainable throughout the company, Ceratizit will evaluate the entire value chain with regard to environmental, social and governance criteria (ESG), while also including company partner cooperation.

Ceratizit is initially focusing on three major levels to quickly and significantly reduce its own carbon footprint. The company plans to increase its use of secondary raw materials to over 95%. Compared to primary raw materials from ore, this processing is said to require 70% less energy and reduce CO2 emissions by 40%. A positive side effect is the safeguarding of the supply chain for raw materials, so that both customers and Ceratizit benefit twice.

Another focus is on the power supply. Ceratizit plans to switch the power supply of all sites to green electricity from wind, solar and water power in the next few years. Closely related to the change in power supply is the hydrogen supply. Hydrogen is used as a production medium in the hard metal industry, especially for the production of tungsten powder. Up till now, hydrogen has mainly been obtained from natural gas by steam reforming, referred to as “grey” hydrogen. Ceratizit plans to use “blue” hydrogen, which is produced from water by electrolysis with green electricity. For this purpose, Ceratizit will cooperate with its existing suppliers and also build its own electrolysis plants.

The first milestone in the implementation of the new strategy is 2025, by which time Ceratizit foresees not only being CO2 neutral — to offset all emissions along the entire supply chain — but also reducing actual emissions by 35% compared to the reference year 2020. The second stage, 2030, envisages a reduction of 60% compared to 2020 with the help of further measures.

The company says its most ambitious goal, however, is the achievement of “net zero” by 2040 — a target expected by the Paris Climate Agreement for 2050.

“Reducing CO2 emissions along the entire value chain by at least 75% by 2040 is without question a challenge,” Wolter says. “However, with a view to future generations, we see no alternative to this path and are pleased to also let our customers participate in this through products such as our GreenCarbide rods and our award-winning SilverLine milling cutter with sustainability formula as well as through a wide range of services.”