Caron's DTect-IT Sensor and Software Suite Capable of Various Machine Monitoring Applications

Caron Engineering’s DTect-IT, originally designed only for vibration detection, is now capable of communicating with multiple sensors, including vibration, strain (measuring force), high-precision power and analog.

Share

Caron Engineering’s DTect-IT, originally designed only for vibration detection, is now capable of communicating with multiple sensors, including vibration, strain (measuring force), high-precision power and analog. The product’s accompanying software provides multiple analysis options for monitoring sensor data.

Using limit analysis, the user can set limits to monitor any of the compatible sensors. DTect-IT has a learn mode to automatically set limits based on the acquired (learned) sensor data; limits can also be set manually using adjustable sliders. When a defined limit has been met or exceeded, the software triggers alarms and notifications. Common uses for limit analysis include barfeeder vibration, bearing vibration and fault detection.

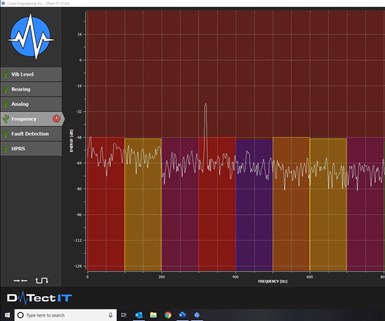

With frequency analysis, DTect-IT can monitor the frequency levels of any sensor and set magnitude limits to monitor and detect anomalies within specific frequency bands. Alarms and notifications are generated when magnitude limits (measured in decibels) are exceeded.

The combination of sensor options and analysis options (with the ability to run multiple simultaneously for each sensor) increase the number of possible applications for the system. In addition to monitoring barfeeders and bearings, other applications include tool wear and breakage detection, yoke strain detection, tapping operations, coolant and temperature monitoring, machine health, preventive maintenance, and more.

DTect-IT is best for monitoring up to four tools, the company says. It can run on its own or connected to the CNC to command start and stop variables. When connected to the CNC, it can set sensor levels and alarms with variables that can be used by the part program to make adjustments. DTect-IT has a data collection analysis to collect raw data from any sensor (up to 62,500 data points/sec.).

All monitored data is stored and can be accessed with the DTect-IT Viewer for inspection, review and analysis. MTConnect compatibility provides seamless communication with shopfloor automation systems.

Related Content

-

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

Taking Machine Monitoring from Data to Action

What will define the next stage of machine monitoring software? MachineMetrics’ Rutherford Wilson believes the answer will look something like a manufacturing execution system.

.png;maxWidth=300;quality=90)