Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Share

Ceratizit has updated its EcoCut indexable inserts with the Dragonskin coating for ISO-P materials. Now referred to as EcoCut-P, the inserts reportedly achieve 15% greater performance than the predecessor models, according to the company’s tests. Due to the coating’s optimized layer structure, the inserts can increase tool life and reduce machining time.

The coating’s mechanical post-treatment induces a state of residual stress in the layer surface, which increases process security. The Dragonskin grade CTCP425-P — with advanced AL2O3-TiN CVD coating — is well suited for applications that require uninterrupted cuts. It delivers wear resistance at increased cutting speeds. When it comes to general steel machining with interrupted cutting, the AL2O3-TiN CVD Dragonskin grade CTCP435-P is said to excel in poor machining conditions and in all applications where a high degree of toughness is required.

In addition to updating its EcoCut lineup, Ceratizit introduces two new toolholding and workholding solutions.

Designed for flexible clamping for multi-axis machines, the PolyClamp Verso from Ceratizit is designed for use in three-, four- or five-axis machines, where it easily clamps all part variants. The system’s jaws are slimmed down for this purpose, while enabling more jaws to be clamped per base rail for clamping larger unmachined or finished parts. A scale lasered onto the centric vice enables the jaws to be positioned evenly and precisely on the rail. The PolyClamp Verso is equipped with a quick-change system as standard. Using just two screws, the fixed and adjustable jaws are released, removed upwards or repositioned. This reduces setup times because each jaw is individually removable without having to dismantle the others.

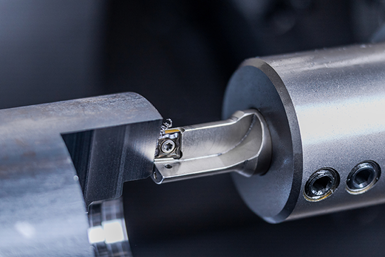

Additionally, the company introduces its MaxiLock-N turning toolholders, which incorporate two internal coolant holes that aim coolant directly at the cutting edge to prevent wear and ensure stable processes. Using these coolant holes, nozzles direct coolant to the clamping flat from above and to the flank from below. This additional flank cooling reportedly contributes to the tool’s ability to extend tool life by 60% compared those that cool only at the clamping flat.

Related Content

-

Shop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

5 Tool Setting Techniques

Each tool setting technique has merit, and it depends on where you are as a shop and the type of work you do, as cost and efficiency all come into play.