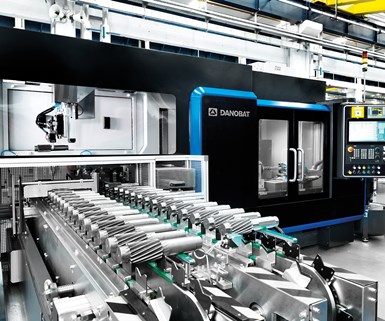

Danobat's LG External Grinder Features Versatile B Axis

Danobat’s LG range of external grinders is designed for tough production work, providing flexibility and precision while also allowing for customization to meet specific application requirements.

Share

Danobat’s LG range of external grinders is designed for tough production work, providing flexibility and precision while also allowing for customization to meet specific application requirements. The LG range was developed for the manufacture of highly complex parts such as hydraulic precision components, gearbox transmissions, and cutting tools, cams and components with eccentric diameters.

According to Danobat, the B axis is what sets the LG series apart from similar machines. It can be equipped with various wheels and can incorporate a range of accessories including measuring devices and super-finish stations. The B axis is driven by a built-in motor, which renders positioning more precise.

The machines offer high precision and repeatability because of the natural granite beds and linear motors, the company says. They also feature glass scales.

The wheel head, which is equipped with cooled electro-spindles, can reach a maximum peripheral wheel speed of 120 m/sec., covering the range necessary for grinding with both conventional abrasives (45-60 m/sec.) and superabrasives (20-120 m/sec.) at maximum torque. LG grinders are available with a variety of different wheel head configurations.

Accessories include moving tailstocks, counter spindles, pre-/in-/post-measuring devices, CNC steady rests, automatic taper adjustment, loading/unloading systems and more. The machines also incorporate Danobat’s DoGrind software.

Related Content

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.