EDM Network's Wire EDM Series Provides Reusable Wire

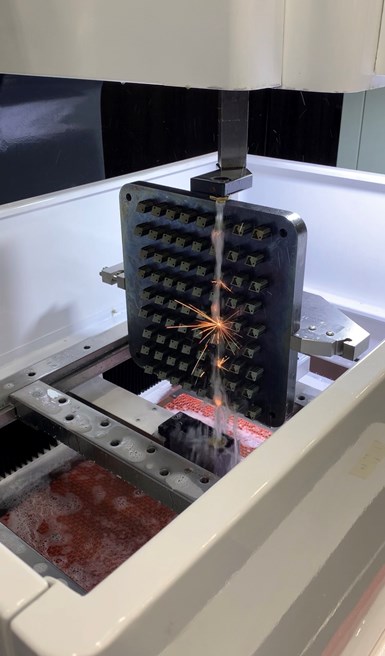

The EDMMax 434W is a four-axis wire EDM that uses a 0.007" diameter molybdenum wire, which draws the water-based dielectric through the cut, cooling it and pulling the small chips out of the kerf at a very fast rate.

Share

EDM Network Inc.’s EDMMax 434W is a four-axis wire EDM that uses a 0.007"-diameter molybdenum wire. EDM Network says the wire can be reused until it needs to be replaced after approximately 24-48 hours of machining. Fast wire EDMs are not flush dependent, meaning that the wire will not break in interrupted cut-off applications. The high tensile molybdenum wire draws the water-based dielectric through the cut, which cools it and pulls the small chips out of the kerf at a very fast rate.

The EDMMax 434Ws are full, four-axis simultaneous wire EDMs that can cut programmed shapes as well as tapers up to 5 degrees per side. There is an onboard programming system included, as well as a USB and LAN port for data loading from programming systems.

The EDMMax 434W series is available in travels of 400 × 300 × 410 mm high, 630 × 500 × 625 mm high and 1000 × 800 × 1050 mm high, which EDM Network claims covers the largest 3D metal printers on the market today. The company offers onsite set up and training included at no additional charge.

Related Content

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.