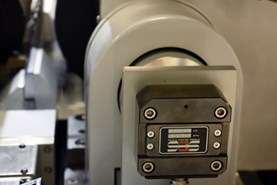

Glebar's Wheel Balancing System Cuts Balancing Time by 90%

Glebar Company’s Automatic Work Wheel Balancing System reduces the balancing time for grinding wheels and ensures higher-quality surface finishes.

Share

Glebar Company’s new Automatic Work Wheel Balancing System dynamically balances the spindle-through controls of grinding wheels using the HMI. The company says the automated system is more precise than a traditional system, better ensuring repeatable, high-quality surface finishes. As a result, the balanced wheel lasts longer and doesn’t need as frequent dressing.

“The Automated Balancing System reduces the time spent balancing the work wheel by as much as 90%,” says Mark Scanel, vice president and general manager of Glebar Customer Care.

Technicians can use real-time balance conditions as indicated on the HMI to predict when the wheel needs rebalancing before the surface finish degrades. With the Automatic Balancing System, Glebar says operators can balance the wheel successfully in as little as five minutes.

Glebar lists the automatic wheel balancing system as available with its TF-9DHD Infeed/Thrufeed Micro Grinder, GT-9AC Guidewire Grinding Machine and GT-610 Automated Infeed/Thrufeed Centerless Grinder.

Related Content

-

Is AI Ready to Tackle High-Mix Grinding? Interview with GrayMatter Robotics Co-Founder

GrayMatter Robotics co-founder Satyandra Kumar Gupta explains how the company’s AI-powered Scan&Grind system tackles weld blending, surface finishing and gate removal on metal parts — and why embodied intelligence is key to automating grinding in high-mix environments.

-

Facilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

-

M&M Quality Grinding Bars Support High-Volume Production

PMTS 2025: M&M Quality Grinding provides precision grinding services for a variety of materials, including titanium, stainless steel, alloys and plastics.

.png;maxWidth=300;quality=90)