Hamar Laser Alignment System Streamlines Turning Setup

The L-703S system aligns headstock spindle axes to guideways and subspindles and tailstocks on lathes, OD/ID grinders, turning centers and similar machines.

Share

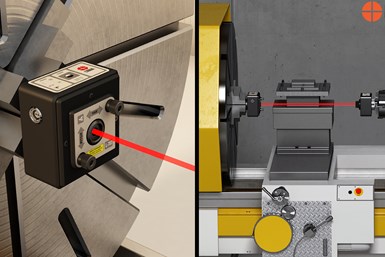

Hamar Laser Instruments Inc.’s L-703S Four-Axis Lathe and Turning-Center Spindle Alignment System features an “S” variant of Hamar Laser’s L-703 Laser.

The new L-703S Laser mounts directly into spindle chucks and collets for aligning headstock spindle axes to guideways and subspindles and tailstocks on lathes, OD/ID grinders, turning centers and similar machines. The L-703S may also be used for guideway straightness checks during preventive maintenance and assembly, and for checking surface plates.

Rod Hamar, president of Hamar Laser Instruments, says, “Our team’s design allowed us to reduce size, cost and complexity, increase accuracy and get rid of annoying wires by adding Bluetooth communications. With a 40% reduction in axial space over our previous L-700 model, the L-703S is much better suited for smaller lathes and turning centers.”

The L-703S Laser is said to be suited for all kinds of turning applications, from small CNC turning centers and Swiss-type machines to large-bed lathes. With a range of up to 50 ft (15 m), the laser can also quickly and easily check the alignment of even very large lathes.

The L-703S System features Hamar’s T-1296 Five-Axis Wireless Spindle and Scan Target, which checks all four alignment axes of a headstock spindle relative to the tailstock. The T-1296 offers a center resolution of 0.00001" (0.00025 mm) and angular resolution of up to 0.00002"/ft (0.002 mm/m). Hamar says this level of accuracy can significantly improve machine performance, reduce scrap rates and increase productivity.

The T-1296’s data updates in real time, so alignment errors can be fixed easily and quickly without changing the setup. The new system reportedly aligns machines up to 70% faster than conventional methods, such as use indicators and alignment bars. According to Hamar, setup requires minimal training.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Using Digital Tap Testing to Measure Machining Dynamics

Tool-toolholder-spindle-machine combinations each have a unique vibration response. We can measure the response by tap testing, but we can also model it.

-

AI Creates CAD Files From Scan Data

While 3D visual scanners are useful, converting a visual scan to a usable CAD file can be a time-consuming process. With generative AI, it may be much simpler and faster.