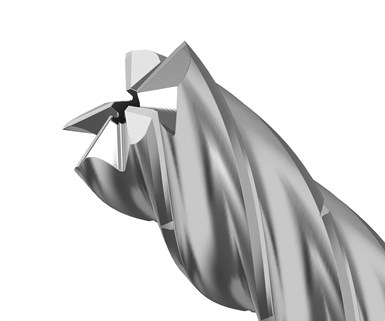

Kennametal's KOR 5 End Mill Enables Higher Feed Rates Roughing Aluminum

Kennametal’s KOR 5 solid carbide end mill is designed for high-speed aluminum roughing in aerospace applications.

Share

Kennametal’s KOR 5 solid carbide end mill is designed for high-speed aluminum roughing in aerospace applications. The five-flute tool is said to allow for increased feed rates of 66% compared to three-flute tools.

A tapered core, variable-pitch design and 35-degree helix reduce chatter and tool deflection, the company says. Through-tool coolant flushes chips away while reducing heat. The tool’s chip splitter pattern is designed to break up long chips to avoid recutting while also contributing to surface quality.

The KOR 5 enables machining with low radial engagement but high depth of cut, resulting in higher metal removal rates than traditional methods, according to Kennametal. Use with the company’s Safe-Lock shanks increases the tool’s predictability and prevents pull-out at higher feed rates.

Related Content

-

Inside the Process of Cutting Tool Recycling

Global Tungsten & Powders, part of the Ceratizit Group, sheds light on the processing steps that convert a shop’s used inserts into new tools and other applications.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.