Machining Facilities Launch Drives American Manufacturing

New five-axis machining center accompanies the opening of 40,000 foot expansion to Ingersoll Machine Tools facility.

Share

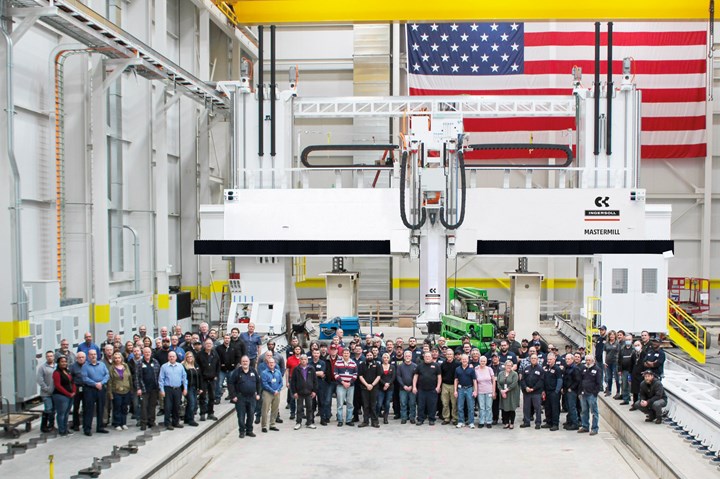

Ingersoll Machine Tools launches its largest and most advanced machining center, the five-axis MasterMill, as part of a new 40,000 square foot expansion for manufacturing, assembly and extended testing facility in Rockford, Illinois.

The MasterMill and facility are initially undertaking complex machining for the US Navy and manufacturing large components for the Giant Magellan Telescope. The company says the MasterMill and facility also spearhead the growth of American manufacturing, private-public partnerships, job creation, skills advancement and development of young manufacturing leaders.

The grand opening event includes advanced manufacturing demonstrations using MasterPrint Robotic, Ingersoll’s robotic version of its XL thermoplastic 3D printer. There are also demonstrations with MasterPrint Metal, the world’s largest metal 3D-printer, and the Mongoose Hybrid, Ingersoll’s multi-process composite manufacturing platform.

Mongoose is used for space, aerospace and defense projects. It plans to soon produce the main structures for the world’s largest optical telescope, which will be assembled in the new building.

Ingersoll Machine Tools provides many other advanced manufacturing processes while also supplying additive and subtractive machine tools for the aerospace, defense, energy and all heavy industrial sectors worldwide. Together with Innse-Berardi, Ingersoll constitutes the Camozzi Machine Tools division of the Camozzi Group.

Related Content

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

How to Build Out a Machine Shop for Submarine Parts

Five-axis large-format machining has given Granite State Manufacturing the ability to take on complex submarine parts — and has also worked as a recruiting tool for experienced machinists.

-

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.