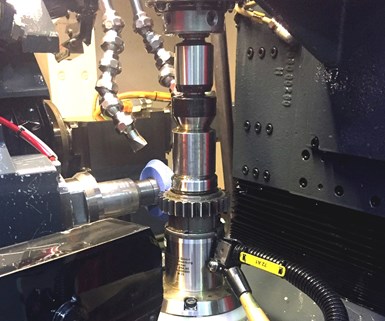

Ringspann's HDDS Mechanical Clamping Mandrel Increases Process Security

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing.

Share

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing. The HDDS, an inner clamping system, is marketed as a mechanical alternative to hydraulic expanding mandrels commonly used in gearmaking. It provides true running accuracy of equal to or less than 5 microns and achieves absolute expansion some four times larger than many other hydraulic clamping fixtures, the company says.

“Our HDDS can take up workpieces with bores of up to tolerance class IT10,” says Production Manager Joe Thompson. “Most hydraulic clamping fixtures, meanwhile, are only suited to take up workpiece bores up to tolerance class IT7.”

Because mechanical fixtures do not leak, they provide more process safety in series production than hydraulic fixtures, the company says, adding that even the smallest leaks can lead to process interruptions, malfunctions and increased repair outlay. The only source of wear for Ringspann’s HDDS is its clamping disks. Furthermore, the clamping mandrel doesn’t need to be taken from the spindle to replace these disks.

Related Content

-

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

-

Reducing Chatter and Strain Through Pressure Monitoring

Loss of fixture pressure can cause problems from chatter to thrown parts. Pressure monitoring helps keep fixtures stable and operations on target.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

.png;maxWidth=300;quality=90)