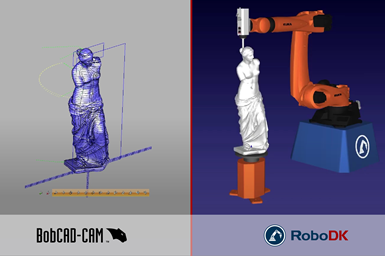

Robotics Programming Plugin for CAD/CAM

The new plugin enables users to seamlessly generate robot machining paths right from within the BobCAD-CAM interface.

Share

Software providers RoboDK and BobCAD-CAM have announced their partnership by releasing a new plugin that is said to make robot machining more accessible to machinists.

The RoboDK plugin for BobCAD-CAM is now available for all users with both software packages. According to the companies, this plugin combines the robust machining-focused features of BobCAD-CAM with RoboDK's powerful robot programming features. Users can now seamlessly generate robot machining paths right from within the BobCAD-CAM interface. BobCAD-CAM is available as a stand-alone product or as an add-on to the popular CAD programs Rhino 3D and SolidWorks.

To use the new plugin, users simply install it to their BobCAD-CAM installation. They can then access the main functionality via the new panel that's added to the BobCAD-CAM user interface. They can send machining paths to the robot at the touch of a button and tweak the robot program within RoboDK if needed.

With this plugin, machinists can now easily program robots for a wide variety of machining applications, all from within their familiar BobCAD-CAM interface. The companies say that various applications can benefit from large-workspace robot machining, including milling of positives for mold making, large-scale sculptures, trimming of molds and complex hole drilling.

Related Content

-

CAM Copilots and the Next Digital Shift in American Machining

As AI reshapes programming and automation, Mastercam is betting on a future where human expertise and intelligent software evolve together on the shop floor. A conversation with Mastercam President Russ Bukowski.

-

The Smarter Way to Take Full Control of Your CNC Machine Shop

Designed to bridge the gap between CAM programmers and shop floor operators, SolidShop provides a seamless, real-time solution for managing G-code, tracking production and eliminating costly mistakes.

-

Advanced Tool Paths, Simple Implementation

Programming advanced tool paths used to be a complex, time-consuming task. Canned cycles in CAM software have now made them more accessible than ever.

.png;maxWidth=300;quality=90)