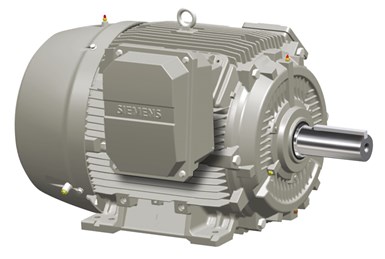

Siemens Announces Simotics SD200 as Low-Voltage Offering

Providing high productivity and energy-efficient operation in all torque ranges, these new cast-iron motors are built to power pumps, fans, compressors, hoists, winders and similar equipment in harsh environments.

Share

At this year’s annual EASA Convention and Solutions Expo in Fort Worth, TX, Siemens announced the Simotics SD200 severe-duty motor in frame size 440 as its latest low-voltage offering.

These cast-iron National Electrical Manufacturers Association (NEMA) motors are designed to provide high productivity and energy-efficient operation in all torque ranges. They are well suited to power pumps, fans, compressors, hoists, winders and similar equipment in harsh environments. The SD200 motors offer 75-800 hp output and feature 444-5013 cast-iron frames for operation in 460 V and 575 V ranges. A wide selection of options is offered, including IP56 ingress protection, encoders, brakes and blowers.

On these motors, the frame, end-shields, fan guard and terminal box are all cast-iron. Complementing this construction are zinc-plated hardware, epoxy paint and stainless-steel nameplates for long life and easy identification. An offset rotor bar provides improved efficiency, while larger bars and end rings reduce resistance, according to the company. Each die-cast aluminum rotor assembly is dynamically balanced, which reportedly extends bearing life, and includes a high-strength C1045 carbon steel shaft. C5-grade steel laminations and copper magnet wire are standard.

For insulation, the Class-H non-hygroscopic system with NEMA Class B temperature rise provides an extra margin of thermal life. The insulation system makes these motors suitable for variable speed drives in constant torque (4:1) and variable torque (20:1). All windings are tested for Corona Inception Voltage (CIV).

Oscar Palafox, the Siemens product manager for low-voltage NEMA motors, explains, “One of the features of the SD200 is its flexibility in the field, as the motor can be switched from F1 to F2 and F3 orientation with ease. Full H-Class conformity provides winding protection, while the swivel hooks are a significant improvement over eyehooks for handling of these heavy units. Shaft current remains more consistent for better uptime.” Palafox further notes this new line affords users Division II, Class 1 (gas) and Class 2 (dust) protection.