TDM Systems' Global Line 2019 Software Combines Workflow, Tracking Capabilities

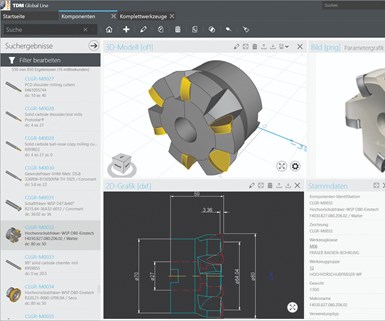

With the new release of TDM Global Line 2019, TDM Systems offers many of the functions of its core solution.

Share

With the new release of TDM Global Line 2019, TDM Systems offers many of the functions of its core solution, which includes TDM Shopfloor Manager, TDM Production Document Management, graphic functions and TDM WebCatalog.

“The global use of a central database results in massive IT cost savings, productivity increases and synergies that span multiple locations,” explains Eugen Bollinger, vice president of sales. “In order to increase the added value for the user even further, we have expanded the configuration options in TDM Global Line 2019 and developed new modules.”

TDM Shopfloor Manager is a tool designed to enable comprehensive workflow management, incorporating booking functions and interfaces for crib systems, presetting devices and machines as well as for higher-level systems such as MES, FMS and ERP. Users can now create multiple shopfloor configurations in order to depict workflows in various production areas. Individual status management enables a user to define the tool status themselves within the workflow.

TDM Production Document Management enables users to assign as many documents as they wish to the production resources via a drag-and-drop function, either in the form of a link to the actual saved location or as a copy on the TDM Global Line server.

With the release of TDM Global Line 2019, upon registering with TDM systems, users will have access through the TDM WebCatalog to the latest tool catalogs in the cloud. This means users can obtain consistently up to date, verified tool data from leading manufacturers.

Related Content

-

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.