WFL's New Software Enables Mobile Machine Monitoring

WFL’s myWFL displays machine and program states over time, productivity and technical availability on the control system, PC or mobile device via a web browser.

Share

WFL has introduced a new software solution for operational data acquisition and predictive servicing. The new software tool, myWFL, consists of the myWFL Cockpit operational data acquisition software, the myWFL Energy optimization tool and the myWFL Condition Monitoring System. Machine and program states over time, productivity and technical availability will all be displayed either on the control system, PC or mobile device via a web browser.

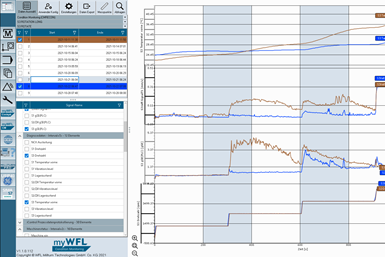

myWFL Cockpit is an operational data acquisition system that displays the machine state, performance, modes of operation and override settings over time. Operating hours, channel status, active NC program, active tool and program runtime are also displayed. Data is collected and stored locally on the control system and can be viewed on the control system display. The progression over time and current values of the ambient temperature and the temperature in the milling spindle housing are also recorded and displayed in myWFL Cockpit.

Another feature is the myWFL Energy energy usage measurement device integrated in the myWFL Cockpit, which displays the current power and energy consumption data as well as the energy consumption of each workpiece. Electrical characteristic values such as voltage, amperage, apparent, active and reactive power, power factor, frequency, min/max values, active and reactive energy are displayed. The energy consumption and switch-on times of various units such as the high-pressure coolant pump per workpiece or per NC program run are also recorded and displayed in myWFL Cockpit.

myWFL also features an integrated condition monitoring cycle. When the cycle is running, the friction values of the axes and spindles, as well as the temperature in the milling spindle housing and the vibration or the rolling bearing condition value of the front milling spindle bearing are continuously recorded and stored on the control system. Using Condition Monitoring Viewer, users can select the data of the various Condition Monitoring runs on the control system, graphically overlay them and analyze them over time. This enables for the early detection of possible malfunctions and minimizes unplanned downtimes.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

SolidCAM iMachining and Technology Wizard: Faster Machining and Longer Tool Life

Smarter toolpaths to tackle modern machining challenges.

.png;maxWidth=300;quality=90)