Indexable Inserts from Powder

During the 2013 edition of its biennial “Technology Days” event, Horn treated the press to a tour of its entire manufacturing operation. Here are a few highlights.

Share

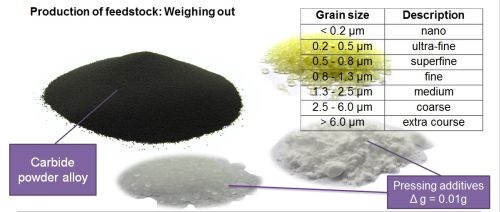

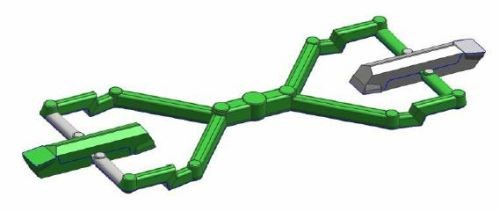

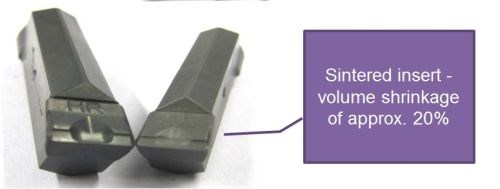

One of the more fascinating aspects of a recent trip to visit Horn in Tubingen, Germany was getting a first-hand look at how the company transforms a powdered mix of various elements into hardened inserts capable of cleaving through even the toughest metal. Click through the picture gallery below to follow this process from start to finish.

Related Content

-

Maximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

-

A New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

-

Understanding Process Damping in Milling Operations

Despite the advances in modeling machining operations over the past decades, process damping remains a topic of interest, including new tool designs that increase the effect.