My Evening at Andretti Autosport

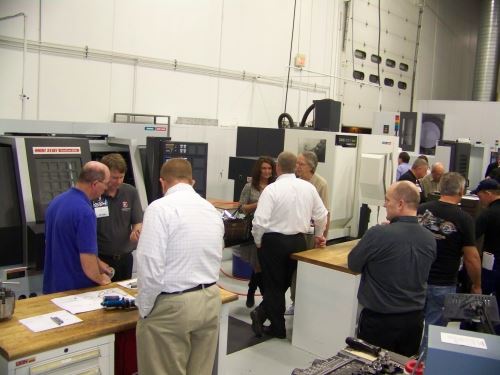

DMG/Mori Seiki invited me to visited Andretti Autosport in Indianapolis. Here’s a slideshow of some of the neat machining- and racing-related things I saw there.

Share

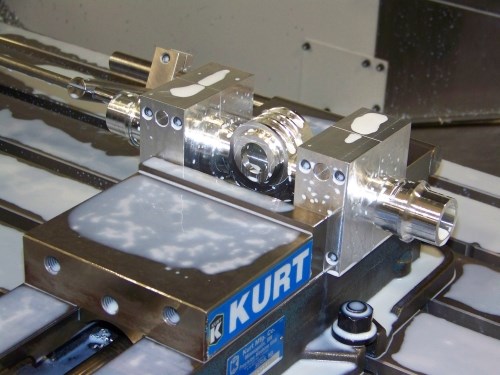

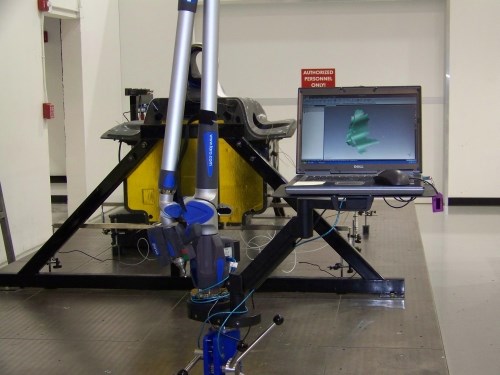

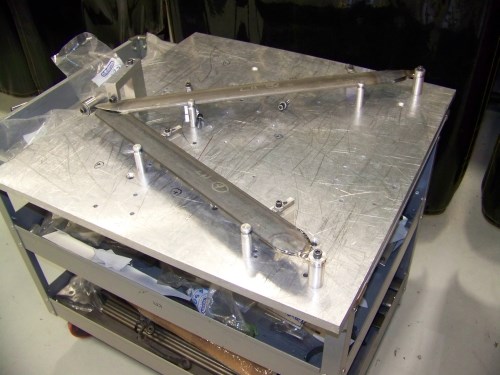

It’s nice when personal and professional interests cross paths. That happened to me last week when DMG/Mori Seiki invited me to visited Andretti Autosport in Indianapolis. DMG/Mori Seiki is one of the Indy Racing League team’s technology sponsors. The team provided three CNC machines—a DuraTurn 2550MC turning center, an NV5000DCG vertical and a DMC635 V Eco vertical—used by the team to create a variety of car components. (Other sponsors include Siemens, Big Kaiser, Faro, Lincoln Welders and Seco.)

The lead machinist at Andretti Autosport commented on how easy the transition was to the new machines in terms of quick installation and training that was provided. This was important because there was no overlap between the removal of the previous machines and installation of the new ones. Ellison Technologies played a key role in helping integrate these machines.

Prior to the event, the team hid all the “super-secret” stuff they didn’t want anyone to see, so we were allowed to take photos throughout the exceptionally clean facility. Here’s a slideshow of some of the neat machining- and racing-related things I saw there.

Related Content

-

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

-

LK Metrology Surface Roughness Probe Enhances Component Inspection

LK Metrology’s Surfacers SRP high-resolution probe is designed for seamless surface analysis within CNC measuring cycles on CMMs.

-

Taiwan Machine Tool Industry Showcases AI Innovations at EMO 2025

The Taiwan External Trade Development Council highlighted AI-powered solutions for precision and sustainability in manufacturing.