New Machines and Automation at Pfronten

Here’s some of what one editor saw at DMG/Mori Seiki’s 2013 open house in Pfronten, Germany.

Share

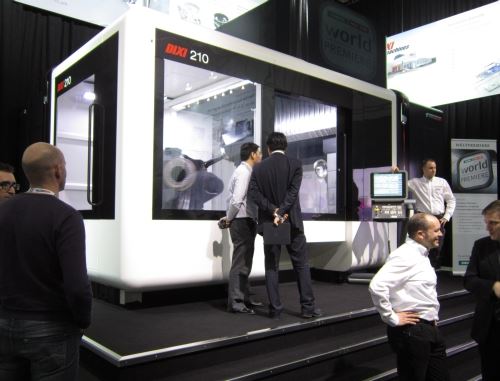

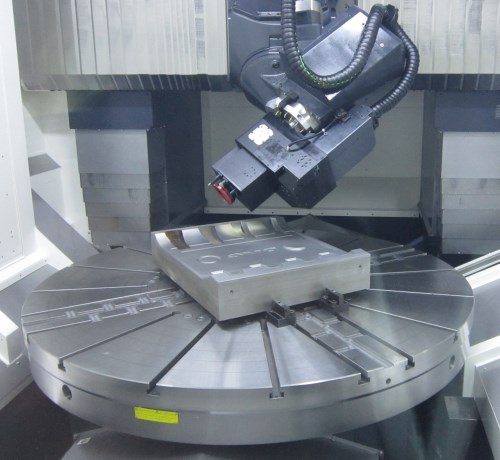

In late January 2013, I attended day one of DMG/Mori Seiki’s open house at its Deckel Maho production facility in Pfronten, Germany. That day there were more than 1,000 attendees who toured the production facility and saw the 70 machines on display (including six world premiers). There also was a wealth of automation solutions on hand, and attendees could see presentations on manufacturing topics that included automation as well as aerospace and automotive.

Check out the slideshow below to see a handful of shots from the event.

Related Content

-

Revolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.