cnctechtalk

Converting Time and Date to a More Useful Format

FANUC and FANUC-compatible CNCs have multiple ways to monitor time. They are accessed by four system variables: milliseconds clock, hours clock, current date and current time. Here’s how to format information in a helpful way.

Read MoreUsing Offset Data to Determine Turret Index Position

Determine the optimal index position based on cutting tools’ current geometry offset settings.

Read MoreChecking Cutting Tool Offset Values

A setup program can be used to test for overtravel issues before a workpiece is run, eliminating program verification delays.

Read MoreExternal Input for Programmed Values

Parametric programming provides three easy ways to access external data.

Read MoreImproving Program Compatibility Among Your CNCs

Put in the effort to eliminate machine-specific programming methods.

Read MoreKeeping Your Company in the Loop

Demand that all employees are constantly learning and staying up to date with the latest manufacturing technology.

Read MoreThe Urgency of Producing a Start-Part

Production cannot begin until the first workpiece is produced and passes inspection.

Read MoreMaking CNC-Related Decisions

The diversity and similarity of components, manufacturing processes and machine tools must be considered to optimize your production process.

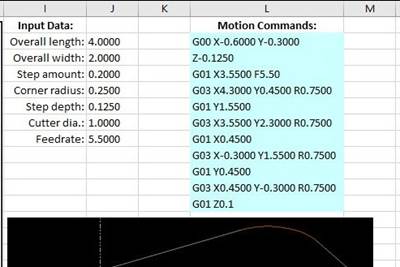

Read MoreSpreadsheets Enable Calculations Similar to CAM Software

Spreadsheet software can behave like a CAM system.

Read MoreAdditive Manufacturing Teaches Designers New Tricks

Considering what is required to design additive parts can illuminate the value of understanding all manufacturing processes, including subtractive ones.

Read More