cnctechtalk

Second-Referencing Variables in Custom Macro

This technique allows operators to query a large number of values using only a few CNC commands.

Read More4 CNC Shop Practices That Hurt Productivity

Stop employing these four common CNC shop practices to make better use of employee and machining time.

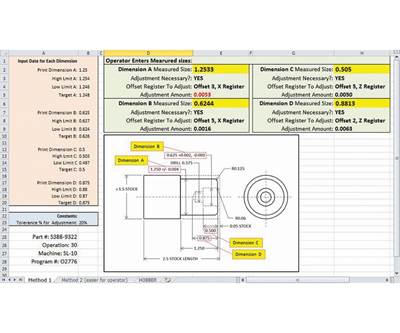

Read MoreMobile Spreadsheets for Sizing Adjustments

This is one area in which operators often struggle, so provide a reference tool to make the job easier.

Read MoreIdentifying Machines from Within CNC Programs

The technique outlined here offers a seamless way for a single CNC program to be used when a job is run across different machines.

Read More7 Suggestions for Process Documentation

Drawings that include these seven details can help clarify specific operations.

Read MoreChanging Program Behavior

User-defined codes allow you to make minor method changes to machine workpieces without reprogramming.

Read MoreCNC Machining: Programming the Appropriate Rates for Your Tool

A bit of math is involved in programming the appropriate rates for a particular tool.

Read MoreConflicting CNC Applications

Almost every critical feature can be used in multiple ways. Be aware of the options, and choose those that are most appropriate for your specific applications.

Read MoreDeveloping an In-House Training Curriculum

You’ve decided who you’re going to train. You’ve assessed your CNC operator needs. Now it’s time to figure out exactly what content you’re going to teach.

Read MoreTraining to Meet Your Specific CNC Operator Needs

You’ve identified the right candidates and decided to train them in house, now how do you make sure the training actually covers what your particular shop needs?

Read More

.png;maxWidth=300;quality=90)