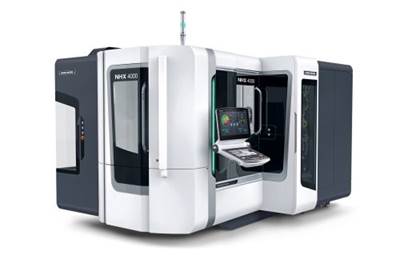

Horizontal Machining Centers

Second-Generation HMCs Optimized for Shorter Tools

DMG MORI’s NHX 4000 2nd Generation and NHX 5000 2nd Generation horizontal machining centers are said to be suitable for single-part manufacturing ranging to serial production.

Read MoreThe Decision Not to Automate Fully

Robotic automation for this machining line was feasible, but the company chose to run it 24/7 with a staff hired just for this job.

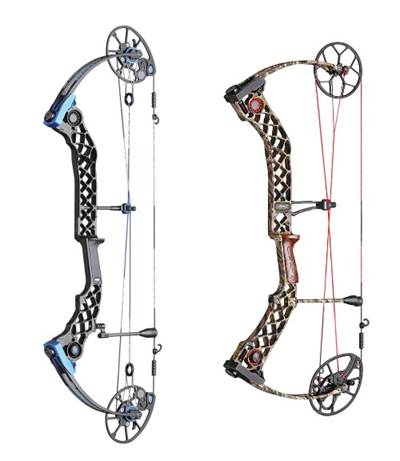

Read MoreHMCs Help Bow Manufacturer Improve Technology, Productivity

By incorporating a Makino a51nx horizontal machining center into its production process, Mathews Inc. was able to increase its efficiency and keep bow production in-house.

Read MoreA Production Line Takes Shape

Although Pointe Precision built its reputation on low-volume, high-complexity aerospace and medical parts, its expansive high-volume production line may be its biggest success to date. Sound decision-making and attention to details at every step are the keys to this success.

Read MoreMulti-Pallet HMCs Reduce Setup Time

Incorporating Kiwa horizontal machining centers from Methods Machine Tools helped Baum Precision Machining Inc. reduce setup time and improve productivity.

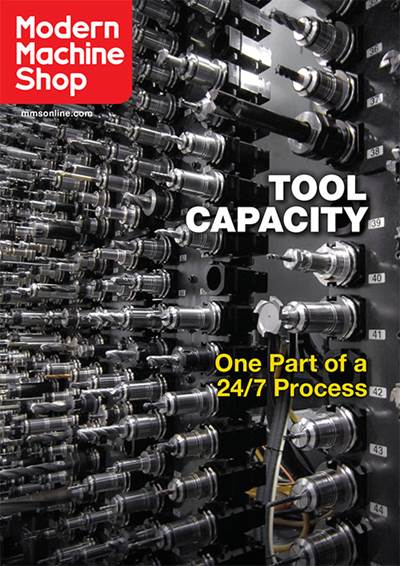

Read MoreAdopting a 24/7 Mindset

This shop considered a number of factors before establishing an effective process to run an HMC cell around the clock for applications in aerospace, oilfield and other industries.

Read MoreFlexible Manufacturing System Shortens Lead Times

A Makino MMC cell and a81 machines provide a flexible production environment that helped Roush Industries take on a wider variety of work with shortened lead times.

Read MoreMachines Offer Parallel Kinematics for Aluminum Components

Dörries Scharmann Technology (DST), a subsidiary of Starrag Group, extends its Ecospeed range of parallel kinematics machines for productive machining of aluminum structural components in the aerospace industry.

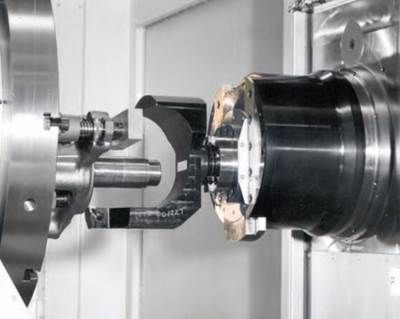

Read MoreHMC Delivers Turning, Drilling, Milling with Single Clamping

The Heckert DBF 630 HMC, available from Starrag, enables turning, drilling and milling of non-rotational, asymmetrical parts in a single clamping with one toolholder.

Read MoreHow Much Can Unattended Production Add?

Using a horizontal machining center, this shop kept production going through two 10-hour shifts per day. That seemed like a lot, but a pallet system enabled the shop to go even further.

Read More