Horizontal Machining Centers (HMCs)

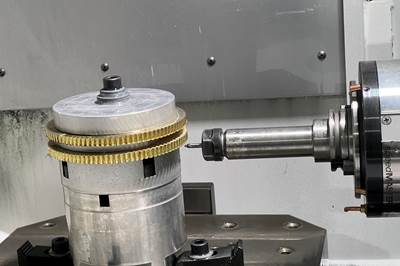

A horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. One reason for this is that the horizontal orientation encourages chips to fall away, so they don’t have to be cleared from the table. More significantly, the horizontal design allows a two-pallet workchanger to be incorporated into a space-efficient machine. To save time, work can be loaded on one pallet of a horizontal machining center while machining occurs on the other pallet.

ESSENTIAL READING

VIEW ALLMachining 101: What are Machining Centers?

Machining centers offer a wide range of possible operations, but that adaptability comes with the need to stay flexible and perform successful measurements at all times.

Read MoreFour Questions a Shop Considering HMCs Should Ask

Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.

Read MoreWhy Tie Payroll Hours to Machine Tool Hours?

J&R Machine uses machine-monitoring data not just to track machine uptime, but also to create a financial index that helps it shape decisions related to equipment, processes, staffing, sales and business in general.

Read MoreBuying an HMC: Peripheral Equipment Considerations

Is it time to move up to an HMC? Let’s consider some of the peripheral equipment that HMC buyers should think about.

Read MoreBuying an HMC: Tooling and Workholding Considerations

Is it time to move up to an HMC? Let’s look at tooling- and workholding-related concerns that those interested in acquiring an HMC will want to keep in mind.

Read MoreBuying an HMC: What Makes Horizontal Machining Centers Different

Is it time to move up to a horizontal machining center? Let’s consider some of the structural, application and design factors that differentiate HMCs from vertical machines.

Read MoreLatest Horizontal Machining Centers News And Updates

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreFryer Offers Compact HMC for Small-Lot Machining

The Fryer HR-40 features a built-in 24" rotary table for multi-sided machining.

Read MoreJTEKT Launches New Series of HMCs

The new FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

Read MorePositioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

Read MoreHorizontal Turning Center Ready for High Production

Romi Machine Tools’ new GL300 S features high-power torque and feed force and is built with a robust monoblock base for ultimate rigidity and precision.

Read MoreThe Debut of an HMC Series

The FH5000 Series from JTEKT Toyoda is compromised of three high-speed horizontal machining centers.

Read MoreFeatured Posts

Digital Demo: X-Series CNC Machine for Extrusions

This unique fixturing system provides maximum hold with minimal clamping footprint to optimize spindle clearance and allow chips, debris and cutoffs to drop below the machining area and away from the spindle. (Sponsored)

WatchThe Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

Read MoreHeavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

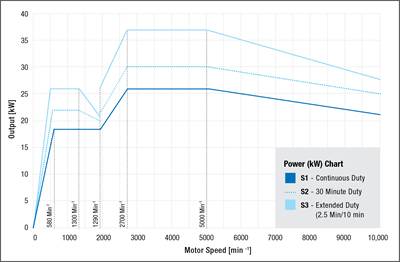

Read MoreBack to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

Read MoreMoving to Horizontal Machining Cuts Shop's Cycle Time by 50%

Adopting horizontal three-axis machining may require much consideration, but Alicat Scientific can attest to almost 50% cycle time reductions with a Kiwa horizontal machine.

Read MoreMachining 101: What are Machining Centers?

Machining centers offer a wide range of possible operations, but that adaptability comes with the need to stay flexible and perform successful measurements at all times.

Read MoreFAQ: Horizontal Machining Centers

What is a horizontal machining center?

Horizontal and vertical three-axis machines differ primarily in the inclination of the spindle, with the spindles of horizontal machines parallel to the surface of the machine table and the spindles of vertical machines perpendicular to the surface, although individual constructions vary widely to support different applications.

What is a machining center?

Typically, machining centers are numerically controlled machines with multipurpose capabilities. This flexibility not only allows for productivity improvements but also allows for one machine to replace several single-purpose machines.

Machining centers provide the ability to perform several operations on a workpiece, from roughing to finishing, with a single setup.

Why should you buy a horizontal machining center?

The simple answer is productivity and profit. Horizontals can easily do three times the work of a comparable VMC. This assertion assumes that the workload to keep the machine busy is available. Without question, you can get more done in far less time using an HMC. With the increase in production, shop throughput is greatly improved. Because multiple operations can be done in a single setup on an HMC, less work in process must move around the shop, increasing efficiency.

Source: Buying an HMC: What Makes Horizontal Machining Centers Different

What are some additional costs of adding a horizontal machining center?

To make full use of the higher-level machine, other parts of the process need to be raised to a higher level as well. Here is a partial list of the additional investments to be made:

1. Inspection equipment.

2. Computers.

3. Coolant.

4. Tool presetter.

5. Fixturing.

6. Tool vending.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)