2014 Autodesk Inventor of the Year: Gear Manufacturer in IN

Once a year, members from the Autodesk Manufacturing Community choose among the past year's monthly “Inventing the Future” honorees to select an Autodesk Inventor of the Year. The 2014 winner was recently announced and it is ITAMCO, a custom gear manufacturer based in Plymouth, Indiana.

Share

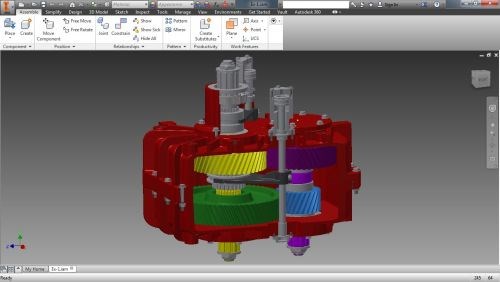

Proficient use of 3D design software from Autodesk distinguishes ITAMCO as a gear manufacturer.

Once a year, members from the Autodesk Manufacturing Community choose among the past year's monthly “Inventing the Future” honorees to select an Autodesk Inventor of the Year. The 2014 winner was recently announced and it is ITAMCO, a custom gear manufacturer based in Plymouth, Indiana.

ITAMCO delivers precision-machined components to original equipment manufacturers in a wide range of industries, including oil and gas and renewable energy; mining and construction; aerospace; and defense. Autodesk Inventor 3D design software, as part of Autodesk Product Design Suite and Autodesk Factory Design Suite, are among the tools ITAMCO leverages to serve its customers more effectively.

It's great to see a precision machining company receive this honor because it highlights the strength of this industry and the importance of the advanced metalworking technology in place there. Although precision gear manufacturing may not have much glamour among the general public, ITAMCO’s products have been used in a number of high-profile applications. NASA has chosen the company’s gears for the mechanical arm that built the international space station. The Department of Defense has used ITAMCO’s gears on its land-based satellite systems.

More recently, the company designed, manufactured and assembled a new gearbox for construction vehicles in record time by using Inventor and Autodesk Inventor HSM Pro. The software enabled ITAMCO to verify the assembly virtually for any interference issues prior to manufacturing and to utilize the advanced computer-aided manufacturing (CAM) capabilities within Inventor HSM Pro for machining the components.

It is also worth noting that ITAMCO’s operations have been enhanced by Factory Design Suite, which enables users to optimize a factory layout in a digital environment before it is completed. The company uses this software to lay out new machining cells and determine the placement of equipment to make sure the plant meets industry standards of organization and efficiency across the factory floor.

Related Content

-

How to Succeed as a Small Swiss Shop: Top Shops 2025

Can small shops succeed with advanced machine tools and software? If so, how do they do it? Read on to learn the strategies that have helped Midway Swiss Turn, our 2025 Top Shops Honoree in Shopfloor Practices, thrive.

-

Refining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

-

Benefitting From an Accurate Data Ecosystem

Data is useless unless it’s true. After decades of false starts with incomplete, unstandardized data collection systems, Alexandria Industries put together a software ecosystem that delivers accurate data to managers, operators and ERP systems alike. In this article, discover its effect on the Alexandria shop floor.