Benefitting From an Accurate Data Ecosystem

Data is useless unless it’s true. After decades of false starts with incomplete, unstandardized data collection systems, Alexandria Industries put together a software ecosystem that delivers accurate data to managers, operators and ERP systems alike. In this article, discover its effect on the Alexandria shop floor.

Share

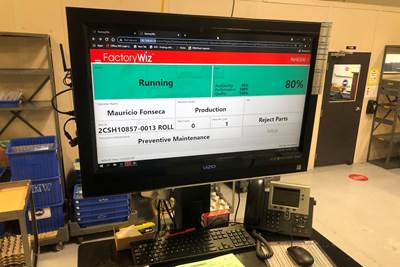

All the data in the world can’t help you make critical decisions if it isn’t accurate. This was an issue that plagued Alexandria Industries’ continuous improvement efforts for decades. Manually recording data would inevitably lead to errors and mismatches, stymieing the company’s ability to implement data-driven solutions. This changed when the Alexandria team sat down and built out a plan for a standardized, hands-off, automatic machine monitoring and data collection system. The team took this plan to several companies, and now uses a custom software ecosystem that integrates FactoryWiz, ISE’s MV2 and Infor XA into a cohesive ecosystem. With this ecosystem, Alexandria Industries has made a start on boosting its productivity across multiple facilities.

As Alexandria Industries has invested more into its data collection ecosystem, its management recognizes that the impact of any errors in the system has grown. While Todd Carlson and Jeff Cypher both say they are pleased with the service they receive from their software providers, they are also training an in-house IT specialist. All images courtesy of Alexandria Industries.

Planning, Letting Go, and Planning Again

Alexandria Industries has been in business since 1966, with a headquarters in Alexandria, Minnesota, and additional locations in Wheaton, Minnesota, and Indianapolis, Indiana. The company was once primarily a manufacturer for telecommunications customers, but after a downturn in the market in the early 1990s, it has courted clients in a diverse range of industries from renewable energy to medical to marine manufacturing and more. Many of the company’s machine tools are vertical three- and four-axis mills or horizontal four-axis mills, though it also maintains some five-axis machining capacity, twin-spindle turning centers with live tooling, a toolroom EDM and equipment for aluminum extrusion.

Its parts are typically either aluminum or plastic, but the shop also handles ferrous materials, with tolerances usually around ±0.003 inch and some tighter holes requiring ±0.0003 inch. The shop focuses on jobs that will lead to repeat business, whether this business consists of 1,000 parts four times per year or hundreds of thousands of parts over a long period. With these kinds of production numbers, optimization of even a few seconds per part can lead to enormous time savings.

Engineer Todd Carlson has known this since he joined the company 25 years ago. His top goal has always been to standardize and improve run rates, and he says he always wanted to collect data straight from the control to facilitate this goal, even from his earliest days using a stopwatch and clipboard. Peak production rarely matched what he recorded, however, and he initially felt this was an operator-side problem. As Carlson matured in manufacturing, however, and as the shop developed its first digital system for downtime coding, he realized that the moment-to-moment variances of operators were unimportant in the grand scheme of things. Instead, he began to see that most of the missing productivity was down to process or machine inefficiencies.

Identifying these with a pencil and a stopwatch was extremely difficult, and the detailed downtime coding system Alexandria implemented wasn’t much better. Jeff Cypher, Alexandria Industries’ director of business integration, says it was very clear that machinists wanted to “make good parts fast,” with data entry for tracking part numbers or downtime reasons being seen as more of an obstacle than an opportunity. Carlson shares that on many occasions, problems were reported as the first downtime code on the list, “extrusion bubbles,” even when this made no sense for the part in question.

Alexandria’s shopfloor management team concluded that its system at the time was not working and put together a plan envisioning an ideal system for the shop. The result would need to be a unified ecosystem that could perform downtime reporting and OEE calculations, be hands-off for shopfloor employees and managers alike, and automatically transfer data to Infor XA (the shop’s ERP system). With this plan in hand, the team approached FactoryWiz and ISE for assistance.

A Three-Fold Solution

Rich Hefner, president of FactoryWiz, says that Alexandria’s big-picture model played a large role in the success of its full software ecosystem. FactoryWiz and ISE collaborated on APIs to facilitate smooth data transfer between the software programs, with ISE also building an API for Infor XA.

Altogether, Alexandria’s software ecosystem consists of three main parts:

- FactoryWiz pulls information out of the machine tool and creates a data set.

- Infor XA acts as Alexandria’s ERP system, using the data to help managers with scheduling and other tasks.

- MV2 acts as the conduit between the two, with connected devices using touchscreens to simplify starting and stopping jobs, as well as the input of a condensed list of downtime codes. ISE’s APIs also enforce the listing of downtime codes, as they require operators to input a code before a machine in downtime can start again.

The Alexandria team has been using robots and cobots for longer than its current data collection ecosystem. Derek Korn wrote an article about the company’s adoption of automation technology in 2020, which is when Carlson says shopfloor automation approached critical mass at the company.

The Exceptional Impact of Standard Measurement

The requirement for downtime codes is important since the categorization of the reason a job went down is as important as the job’s overall equipment effectiveness (OEE) number. Hefner explains it succinctly: “If we don’t measure what those reasons are that sand slipped out of the sandbox, then we don’t really have a chance of trying to improve it.”

Improvement requires accurate data, as well as an end to misperceptions of productivity. When Alexandria first began monitoring OEE, the company assumed they were running at about 85-90%. In reality, they were running at about 20-25%. While a horrifying realization in the moment, the team quickly realized that this low OEE carried an upside: Instead of carrying on with plans to spend money on new capital equipment (as well as a new building to hold it), they could improve their revenue through the much less expensive task of improving efficiency.

But even splitting OEE into its constituent components — availability, performance and quality — was not enough to determine the exact issue behind any particular instance of downtime. This is where the newly pared-back list of downtime codes came in handy, helping narrow down potential causes.

Carlson and Cypher say that this functionality was particularly useful for the shop’s automated cells. The company’s software ecosystem collects runtime and part counts in real time, and can tell exactly when an automated machine would go down in the night. This helps Alexandria’s staff see what brings the machines into downtime, better enabling them to address issues and keep the roboticized cells running longer overnight.

While the robotic cells provide some of the consistency that makes them a particularly good fit for OEE tracking, Carlson and Cypher also acknowledge that the variability of the company’s workload makes it impossible to know just how much of the shop’s OEE improvements can be credited to the software. That said, the scale and timing of these improvements suggests that they are in part driven by the ability to identify and ameliorate downtime causes. For one job, availability went from 22.66% in April 2024 to 72.2% by January 2025. Across the same time period, quality increased from 95.4% to 98.3%, while performance dropped from 87.8% to 66%. Even with the drop in performance (that is, expected cycle time, load and unload time and a small percentage to account for individual variations divided by the actual time taken for the operation), this still marked an overall OEE improvement from 19% to 46.8%.

Alexandria Industries refers to lights-out robotic cells as “Night Rider” cells. Now that the shop has ways to track the start of downtime on its robots, several managers have set goals to increase Night Rider hours.

Building Trust

Of course, these improvements relied on the team getting buy-in from shopfloor staff. Domenic Lanzillotta, sales VP at FactoryWiz, notes of past FactoryWiz implementations that “when you engage people and you empower them, we find that the system is successful and it works and it benefits everyone. When it gets imposed on them or it becomes a punitive system, it typically does not work.”

Alexandria’s strategy for doing so took large inspiration from Carlson’s own shift in perspective for what machine monitoring and data collection can accomplish. Knowing that machinists often just wanted to make good parts as fast as possible, the team presented this system as a way to eliminate the roadblocks for doing so. That is, the system could find pain points in operators’ jobs and help managers and shopfloor staff eliminate them.

This approach brought some success, as did Carlson using FactoryWiz data to shatter common misperceptions on how productive the machines were already. Many operators thought their machines were running at about 75% efficiency, rather than the real 25%. Showing how the specifics of data reveal that larger downtime blocks often come down to process bottlenecks — say, waiting for the inspection team to complete first-article inspection — has brought further success in appealing to staff members concerned that the software will be used for surveilling employees rather than jobs, regardless of stated intentions. After all, as Cypher puts it, “If you don’t have a workforce willing or understanding what it is that you’re going to do with the data, you’re going to fight that.”

To ensure the implementation process was as smooth as possible, Alexandria’s management specifically worked with its operators known to be resistant to technological change. As Rick Reith, senior manufacturing engineer at ISE puts it, this wasn’t a sudden insistence to use the system, but a chance to the company to say, “this is what we’re going to do and why, and let me know what you think about this.” In doing so, the team hoped to receive honest and candid feedback. Equally important, once management was able to address this feedback and convince this group of operators that the system was a good idea, the support of these operators would be a powerful force in getting the rest of the shopfloor staff to consider that the software might have something going for it.

Since the company first implemented its new data collection ecosystem on two machines in February 2023, it has proved successful enough for Alexandria to expand it to over 40 of its machines. Television screens around the shop now show the status of different work centers, which are color-coded for quick reference. Accurate data has improved the company’s costing estimates, and the company now employs an IT person specifically trained to tackle any software issues in the system.

Carlson says that Alexandria’s ownership team is a group of “entrepreneurs that … know what it takes to develop a vision for what you want your organization to look like and have been very focused and strategic in starting out, defining it in their minds and then identifying the elements to bring that to life.” This planning played a large role in the success of the company’s full data collection ecosystem, with clear objectives, needs and processes standardizing a long-standing headache for the shop. Planning how it would roll out the ecosystem and staying open to shopfloor feedback has been equally useful, convincing staff that this system was meant to help them do what they want: make good parts fast.

Related Content

Scaling Up Without Starting From Scratch

In its quest to become a single source for all its customers, sheet metal fabricator GTR Manufacturing long considered bringing machining in house, but a lack of space and expertise held it back – until it found the perfect solution.

Read MoreMachine Monitoring Integrates With ERP to Reduce Errors

By investing in machine monitoring that links machine data with the shop’s ERP system, this machine shop broke down communication barriers and dramatically reduced errors.

Read MoreThe Smarter Way to Take Full Control of Your CNC Machine Shop

Designed to bridge the gap between CAM programmers and shop floor operators, SolidShop provides a seamless, real-time solution for managing G-code, tracking production and eliminating costly mistakes.

Read MoreERP and Process Changes Increase Shop’s Revenue 64% YoY

Implementing ProShop has led to a massive process overhaul at Marzilli Machine. From 2020 to 2021, revenue increased 64% without capital investment.

Read MoreRead Next

Monitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Read MoreIf at First Your CNC Machine Shop Doesn’t Succeed with Robots, Automate Again

Alexandria Industries struggled with its first robotic machining cell. However, the aluminum extrusion components manufacturer — now with more than 20 robots — discovered that by simplifying and standardizing its automation strategy, it could reap the benefits of unattended machining even for relatively low batch sizes.

Read MoreCNC Data Feeds Make Social Distancing Easier

Machine monitoring helps work remotely, avoid close contact on the shop floor and prevent underbilling for lights-out machining.

Read More