A Modular Clamping System for Bulky Parts

Here’s one fixturing alternative for clamping large workpieces such as mold and fracking components.

Share

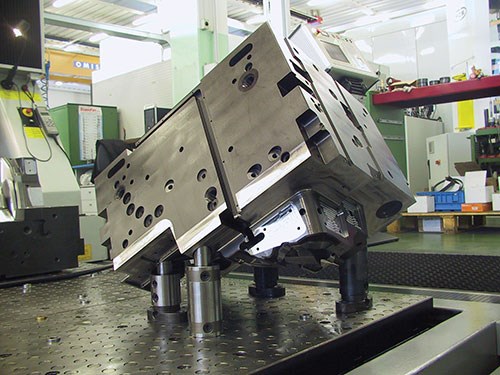

The FCS modular clamping system was designed to minimize setup times, enable machines to access five sides of a fixtured part and provide highly repeatable positioning so parts can be removed and accurately refixtured as needed.

FCS Moulds, now Elmann S.R.L.U., is an Italian moldmaker that sought to develop a standard means of fixturing mold components that would minimize setup times, enable its machines to access five sides of a fixtured part, and provide highly repeatable positioning so parts could be removed and accurately refixtured at the same zero reference points as needed. Ultimately, its goal was to increase its machines’ spindle utilization so it could be more competitive with foreign moldmakers.

The solution it developed eventually turned into a product line that’s well-suited for clamping big, bulky components. Learn how you might benefit from it.

Related Content

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Revolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

-

Maximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

.png;maxWidth=300;quality=90)