Five Observations from PMTS

PMTS marked not just the first machining trade show in over 18 months, but also the first show for our newest editors! Nate Fields and Evan Doran discuss what they learned at PMTS.

Share

The 2021 Precision Machining Technology Show (PMTS) was the first machining trade show in over a year and a half, and hosted over 5,400 attendees on the first day alone. It also served as the first trade show for several new staff members of Modern Machine Shop, including digital assistant editor Nate Fields and assistant editor Evan Doran. Here is a small sample of what they learned in their time at the show:

Haimer was most excited about its new shrink-fit technologies for ER collets that pair with live turning tools. The Power Clamp Air i4.0 used supercooled air to shrink heated tools, right on the show floor.

1. Shrink-Fit is Going Live

Haimer has historically focused on milling, but that does not preclude making turning machines shine as well. For example, the Power Clamp Air i4.0 Haimer demonstrated on the show floor provides shrink-fit heating and cooling for ER collets on the turrets of live-tool lathes. Rather than a liquid cooling system, the shrink-fit solution lives up to its name and uses jets of air.

2. In-Person Events Make Demonstrations Easier

SolidCAM chief operations officer Shaun Mymudes expressed his excitement to see attendees and customers in person for the first time in nearly 18 months. Mymudes stressed the importance of face-to-face networking on the show floor, where manufacturers and developers can demonstrate the benefits of their technologies to customers in real time.

“It’s critical and crucial for us to have CNC machines (at events) and show people the dramatic effect of our software,” Mymudes said. “They don’t sometimes make that connection. ‘Well, you know, you’re just telling it what to cut.’ No. We’re creating a sweet spot for that tool throughout its entire cut.”

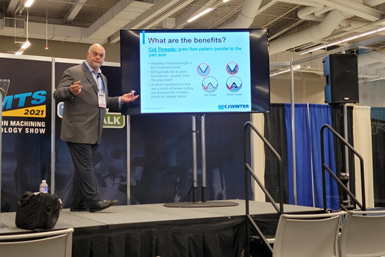

Lib Pietrantoni of CJ Winter delivered an extensive Tech Talk on the benefits of thread rolling over thread cutting.

3. Education is (Thread) Rolling Along

Tech Talks delivered practical advice and technical overviews directly from the show floor. For example, Lib Pietrantoni, director of global sales at CJ Winter, discussed the benefits of rolled threads versus cut threads in an in-depth presentation. Pietrantoni also led a Q&A session about this form of manufacturing — all within a half-hour time frame.

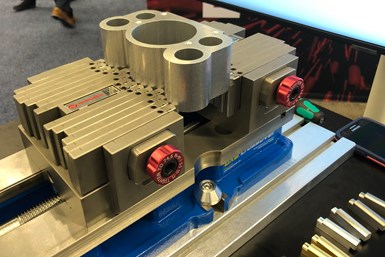

IMI Norgren’s Adaptix Soft Jaw uses a modular approach to soft jaw workholding. The device is in its early days, but already has “fingers” made from several materials.

4. Workholding is Seeing Some Shakeups

With workholding proving vital to lights-out machining and other productivity-enhancing process changes, many manufacturers are experimenting with new workholding devices.

One OEM, Norgren, showed off its Adaptix Soft Jaw, which takes a different approach to traditional soft jaws. Rather than designing and CNC machining a soft jaw for each new program, the Adaptix features lockable “fingers” that are configurable for each new part on a machine. Although the device has yet to hit shop floors, Norgren has already tested several finger materials to broaden the application range for launch.

5. Local Shows Generate Promising Customer Leads

Brian Sawicki, business development manager at Tungaloy, says regional trade shows like PMTS provide opportunities to appeal to specific audiences. For example, he says the presence of many small-part manufacturers makes PMTS ideal for promoting the company’s replaceable-tip drills, high-feed milling tools and Swiss tooling. In fact, he says Tungaloy gained more than 20 customers at PMTS 2019.

Related Content

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreChoosing the Right Drill Type

Specifying the right option for your application can save time and tools.

Read MoreShop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More