"Soft" Automation is Long Overdue

Digitalizing and systemizing the clerical work of quoting and quality control is more achievable and more urgent than ever.

Share

In the first installment of this column, I wrote that my new monthly platform would focus not only on practical applications of data-driven manufacturing, but also “what comes next.” One tumultuous year later, I’m more convinced than ever that part of “what comes next” is as much about the front office as the shop floor.

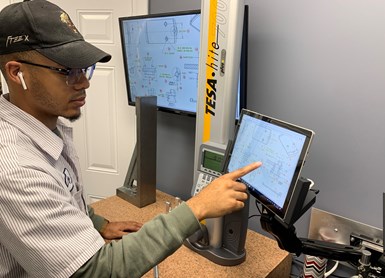

At Marzilli Machine Co., automatic ballooning and report generation dramatically speeds the creation of documents essential to the work of Chris Kancel-Lengyel, quality control inspector.

A case in point is the quick-turnaround manufacturing of PPE earlier this year at Protolabs Inc., a digitalized protoyping and manufacturing company in Maple Plain, Minnesota that has developed its own “soft” automation. The process begins with automated analysis of a CAD model submitted online to an engine that provides near-instant pricing, manufacturability and other information, streamlining typically labor intensive front office tasks. Thanks in part to this front-office automation and its tie-in with the rest of the plant, the company was able to quote urgent orders in minutes and even ship some life-saving parts on the same day they were ordered.

Some manufacturers can never be (or even want to be) like Protolabs’ plant in Minnesota, where quoting automation is only the front end of a system that interfaces more than 500 machine tools as well as 3D printing, injection molding and other equipment. Nonetheless, I wonder sometimes whether shop owners fully understand the capability of tools that are available to, and even designed for, businesses like theirs. One manufacturer’s experience aside, the tumult of 2020 is evidence enough that it is time for more shops to embrace “soft” automation with the same enthusiasm as machine-tending robots.

This does not have to mean developing one’s own software. In a previous column, I wrote about how a company called Xometry invites parts purchasers to submit CAD files online for near-instant part pricing and design feedback. It then delegates jobs to a network of manufacturers according to their capability and capacity. A company called DigiFabster has taken yet another approach by offering a similarly automated, cloud-based front end as an individual service. That is, rather than joining a network, shops use the service individually for their own customers, even adding their own logos and other personalization to the online interface as they see fit.

Whatever the future of these businesses and others like them, CNC machine shops have soft automation options beyond quoting. Consider the example of Marzilli Machine Co., a small shop in Boston that was the subject of our November issue cover story. Owner and founder James Marzilli credits much of this relatively small shop’s growth to an insistence on digitalizing processes wherever digitalization is feasible. To that end, the shop invested in quality control software from High QA that scans, balloons and annotates 2D drawings automatically. This eliminates much of the work associated with generating inspection plans and reports.

I had seen this software before, but only on the floor of a trade show. Learning about its impact on an actual CNC machine shop was an entirely different experience, proving the extent to which shops can achieve significant levels of “soft” automation now. It also convinced me that as more of the necessary tools become available to automate quoting, quality control documentation or other varieties of office work, barriers to adoption could be more mental than technical in nature. As James Marzilli puts it, “Everybody is talking about automating, but what they’re really saying is just, ‘Let’s put a robot in front of this and replace the person.’ They’re not really considering how much manual work goes into just administering the company.”

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreLegacy After Loss: Writing the Next Chapter of a Family-Owned Machine Shop

When a beloved machinist’s passing left his shop in his children’s hands, the three siblings stepped up, transforming the business to honor his legacy and build a new future.

Read MoreRead Next

5 Benefits of Sourcing CNC Machining Work Online

Machine learning saves time, makes pricing fairer, inspires improvement initiatives, and even insulates manufacturing businesses against economic shocks.

Read More5G: From the Cloud to the Machine Tool Workzone

Fifth-generation wireless communications standards demonstrate the potential for process control at all levels of a CNC machining business.

Read MoreJob Shop Automates Quoting and Programming

From quoting and design analysis to the application of tool paths, software automation facilitates custom-machined parts on demand and without middlemen.

Read More