“Intelligent” CAM System Adapts to the Job

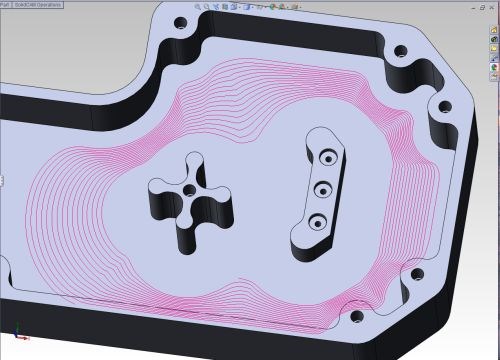

SolidCAM’s iMachining CAM software features an algorithm designed to eliminate potentially time-consuming, trial-and-error approaches to optimizing cutting parameters.

Share

These potentially time-consuming, trial-and-error adjustments happen every day in shops of all types and sizes—a fact not lost on SolidCAM when it developed its iMachining CAM system. This software is designed not only to provide effective tool paths, but also to enable users to efficiently apply those toolpaths according to their own particular preferences and application circumstances. Read this article to find out how.

Related Content

-

Shop Tour Video: You've Never Seen a Manufacturing Facility Like This

Explore Marathon Precision’s multi-process approach to manufacturing, where blacksmiths and hand-forged dies meet state-of-the-art CNC machining. Discover how restoring classic muscle cars and building custom art projects creates a dynamic shop culture — and draws top talent to this unique and innovative metalworking facility.

-

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

-

How I Made It: Montez King

From high schooler pushing a broom on a shop floor to executive director of the National Institute of Metalworking Standards (NIMS), a series of bold decisions have shaped Montez King’s career path.