Seamless Connectivity for Tool Presetter Data

MTConnect benefits Parlec both as a manufacturer and as a technology supplier.

Share

Parlec sees the tool presetter and the tool data it generates as a vital hub in the machining process. However, it’s essential to have reliable communication among the tool presetter, tool data management system, CAD/CAM software, the machine tool CNC and other systems, such as a computerized tool crib and a shop scheduling/ERP system. The ability to interface with this diverse array of systems and devices is a major issue for the company.

“This is the main reason we’ve taken such a strong interest in manufacturing communication standards such as MTConnect,” says Chris Nuccitelli, vice president of this Fairport, New York company. When MTConnect, a royalty-free, open-source protocol for shop floor communication, was introduced about five years ago, Parlec was quick to investigate the standard and apply it to its products as well as implement it in its manufacturing facility. “What we’ve been able to do with MTConnect so far mirrors the state of most other companies who are interested in the standard,” Mr. Nuccitelli reports. “Initial benefits have been encouraging, but we see a much greater potential on the near horizon, especially now that the latest release of this standard includes a comprehensive vocabulary for cutting tools and cutter body assemblies,” he says.

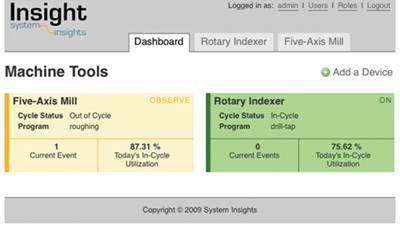

Parlec’s experience is instructive, Mr. Nuccitelli points out, because the company is involved with MTConnect as an end user and as a supplier. The company manufactures its toolholding, boring, tapping, and presetting products exclusively in the United States. On its shop floor in Fairport, all of the Mazak machining centers are equipped with an MTConnect adapter, a software utility running on the CNC to gather machining data issued in the MTConnect format and make the data available to other applications on the shop network. At the moment, Parlec is evaluating shop floor monitoring systems enabled by MTConnect.

Machine monitoring is a priority because the shop floor is set up to run 24/7. “Machine monitoring will help us sustain round-the-clock production, but more important, it will help increase productivity by improving the efficiency of our machining centers,” Mr. Nuccitelli reports. For example, machine monitoring helps managers detect and respond quickly to delays or slowdowns.

From its standpoint as a supplier, the company also sees substantial value in MTConnect. “The first releases of the standard provided only limited options for sharing tool data such as cutter length and diameter, but this gave us an opportunity to create functional MTConnect adapters and agents for our line of tool presetters,” Mr. Nuccitelli says. These serve as a foundation for expanding MTConnect compliance as new applications emerge.

“The big breakthrough in this area is the recent release of extensions to the MTConnect standard for what are called mobile assets, Mr. Nuccitelli points out. Mobile assets include cutting tools, cutter body assemblies, fixturing components and other elements that tend to circulate among machines, storage units, inspection devices, automatic changers and so on. Parlec participated in the development of this extension by being an active member of the mobile assets committee under the auspices of the MTConnect Institute.

The new MTConnect vocabulary for cutting tools is based on ISO13399 (Cutting Tool Data Representation and Exchange), which defines all parameters for cutting tools and toolholder assemblies. Data such as tool length, diameter, primary radius, insert lead angles, clearances, weight and other measurable characteristics can be formatted in compliance with the MTConnect protocol.

“Historically, Parlec has been a leading developer of tool measurement and management systems to organize and communicate tool measurement data,” Mr. Nuccitelli says. Its flagship product in this category is Parlevision PGC Plus 6, a PC-based system for its toolsetters that is designed to act as a networkable conduit of tool measurement data throughout a manufacturing enterprise. This system is highly configurable so users can connect with CNCs, presetters and other software applications. “Over the years, we’ve developed an extensive library of interfaces. MTConnect now gives us a standard protocol that will ease and eventually end the need for customized interfaces,” he says. In addition, Mr. Nuccitelli notes that as third-party software developers create new MTConnect-enabled applications that rely on current, comprehensive cutting tool data, Parlec will be positioned to connect its PGC software seamlessly with those applications.

“MTConnect compliance helps us leverage the capability of our presetters and tool data management software. Going forward, this will be a significant advantage in the marketplace,” Mr. Nuccitelli concludes.

Related Content

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreA New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read MorePicking the Right End Mill

Kennametal global product manager Katie Myers explains how cutting tool features can impact machining strategies for different materials.

Read MoreIndexable Drill Heads Double Profitability

Moving to a robust line of indexable drills enabled this shop to dramatically alter the manufacturing process for a problem part, doubling its profitability.

Read MoreRead Next

MTConnect Is For Real

Introduced at IMTS 2008, this communications protocol for CNC machines and other manufacturing equipment is already helping shops and plants implement effective machine monitoring systems. Although these "early adopters" are motivated by the long-term promise of enterprise-wide efficiency gains, their experience with pilot projects shows that benefits derived in the short term are substantial and worthwhile.

Read MoreGetting Started with MTConnect

MTConnect is a standardized communication protocol designed to help shops and plants integrate every piece of shopfloor equipment into a manufacturing data system. A new "conductivity guide" explains how to start implementing MTConnect to improve productivity on the shop floor.

Read More