Standardized Workholding Saves Shop Hours of Setup Time

5th Axis’ workholding solutions have enabled Will-Mor Manufacturing to achieve vastly better repeatability and stability, cutting setup time and even whole setups.

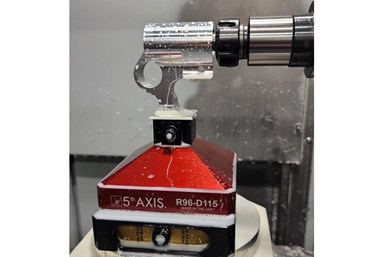

5th Axis’ workholding features promote accessibility for machine tools. The D115 dovetail fixture can make enough of the part accessible to eliminate some setups from three- or four-axis tasks.

Photo Credit: Will-Mor Manufacturing

Long setup times are a drain on productivity and profitability. Fran Roman and Mike Kelly, owners of Will-Mor Manufacturing, felt this issue keenly as their shop grew and acquired more customers over the past decade. The Seabrook, New Hampshire-based manufacturer specializes in tight-tolerance complex milling and turning, as well as fabrication and assembly, for the aerospace, defense and power generation industries. The 90 employees at its 45,000-square-foot facility handle three- and four-axis vertical and horizontal machining centers, vertical and horizontal turning machines, wire EDM and welding. With this kind of diversity in their work, workholding inefficiencies and lengthy setup times have prevented the shop from reaching its full potential.

To solve these issues, Will-Mor turned to 5th Axis, a workholding manufacturer based in San Diego, California. Will-Mor first began using 5th Axis’ V552 vises and, after being impressed by the vises’ performance and versatility, soon invested in the brand’s R96-D115 dovetail fixture and a RockLock base.

Adjustment Period

Will-Mor kicked off a six-month long project when it began switching to its 5th Axis workholding. The overhaul in tooling, workholding, fixturing and CAM paths had to take place in parallel to the production schedule, and its success came down to the work of senior manufacturing engineer Douglas MacKinnon and lead product line programmer Alex Bickford. MacKinnon designed and modeled the new setup, selected the workholding and programmed the fixtures, running technical and practical support throughout the process introduction. Bickford selected the new tooling, assisted in toolpath generation and gathered data — as the operator most familiar with the old process, he was in a good position to identify the process bottlenecks.

Standardizing the base and clamp positions has enabled Will-Mor to run multiple parts on the same setup, with the same work zero.

Tweaking all the details to the shop’s liking — optimizing feeds and speeds, carrying out postprocessor updates to suit zero edits to programs after posting, developing program paths and other process adjustments — extended the project by another three months, but resulted in significant benefits.

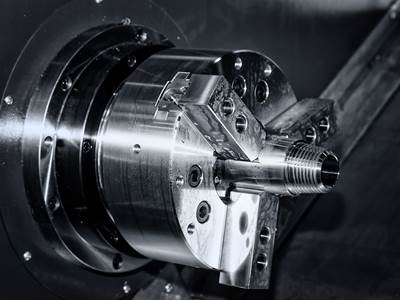

5th Axis’ self-centering V552 vises enabled Will-Mor to reach repeatability of less than 0.0005 inches, ending an era of labor- and time-intensive “dialling in” that involved cutting with stock on and adjusting it.

Photo Credit: Will-Mor Manufacturing

Standard Vises

Will-Mor points out two parts that used to require extensive fixture changes. The parts used different radius jaws based on diameter, as well as different locating pins — and sometimes needed shimming into alignment. With the V552 self-centering vise, these parts now run in the same vise, and Will-Mor has 360 degrees of clearance. The V552’s repeatability of less than 0.0005 inches, along with the low repeatability of other 5th Axis products, ended Will-Mor’s need to “dial in” most of its parts after setup, which had involved cutting with stock on and adjusting it — a productivity sink the shop found unacceptable. The increased repeatability boosted productivity by over 30% and decreased per part cycle times.

5th Axis’ solutions standardized Will-Mor’s setups, removing the need for custom jaws, work and tool offsets, setup-specific quirks and the vast majority of its fixture changes. For one part with five setups per week, Will-Mor reduced the setup times from around six-to-seven hours to between one and two hours. Will-Mor could also now do the entire operation plus some extra machining in one set of serrated jaws. For another job, Will-Mor says it was able to reduce the setup time from around four hours to just about 15 minutes.

Standardizing base and clamp positions through RockLock four-pull-stud bases and dovetail fixturing has increased system usability and drastically cut setup times. It enables Will-Mor to run multiple parts on the same setup, with the same work zero.

Photo Credit: Will-Mor Manufacturing

Accessibility Through Dovetails

The RockLock base from 5th Axis provides even more stringent repeatability than the V552 self-centering vise, at 0.0003 inches, and uses a four-pull-stud system with industry-standard 96 mm or 52 mm stud spacing for maximum compatibility with other major four-pull-stud systems and mounting compatibility with most three-, four- and five-axis tables. It standardizes setups and work coordinates — a benefit which combines with the small footprint of 5th Axis’ D115 dovetail fixturing to minimize both the number of setups and the necessary setup time. For one part, this combination enabled Will-Mor to remove 90% of material in one operation.

Standardizing the base and clamp positions has additionally enabled Will-Mor to run multiple parts on the same setup, with the same work zero.

One of 5th Axis’ signature innovations is the “poka yoke” feature of the dovetail clamps, which prevents operators from misloading vises and fixtures. It also enables Will-Mor to be confident that the stock is both centered and loaded in the proper orientation. The strength and stability of the fixturing resulted in a 40% reduction in scrap.

Related Content

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

Clamping Solution Facilitates Large-Part Vertical Machining

Mitee-Bite Products’ fixtures demonstrated their powerful clamping support in a project with Akron Gear & Engineering to vertically hold a 1-ton ring during machining.

Read MoreStandardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

Read MoreHow to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

Read More

.png;maxWidth=300;quality=90)