Share

In an industry that runs on technological advancements, one aspect of machining has not advanced: the human body. While the machine tools have grown more efficient, the machinists who set up and run them have the same features they did 100 years ago. Chronic pain is—and perhaps has always been—a common problem among those who stand at machine tools and routinely move work in and out of them.

Indeed, chronic pain affects more than 75 million Americans, according to the National Institute of Health. It is the leading cause of long-term disability, and in a manufacturing world struggling to fill job vacancies, it can end the careers of irreplaceable machinists. It can lead to depression, chemical dependency and a loss of vigor—yet we rarely discuss it. Many are willing to see pain as simply part of the job, but one Michigan machinist would not accept it as unavoidable.

Instead, she engineered a solution that cured her own pain by improving on the basic experience of standing. Her invention provides a padded surface enabling the operator at the machine to lean slightly while standing, dramatically changing the forces on the body and eliminating the knee locking that has proved to be the source of her pain.

Grinding Metal for Fun and Profit

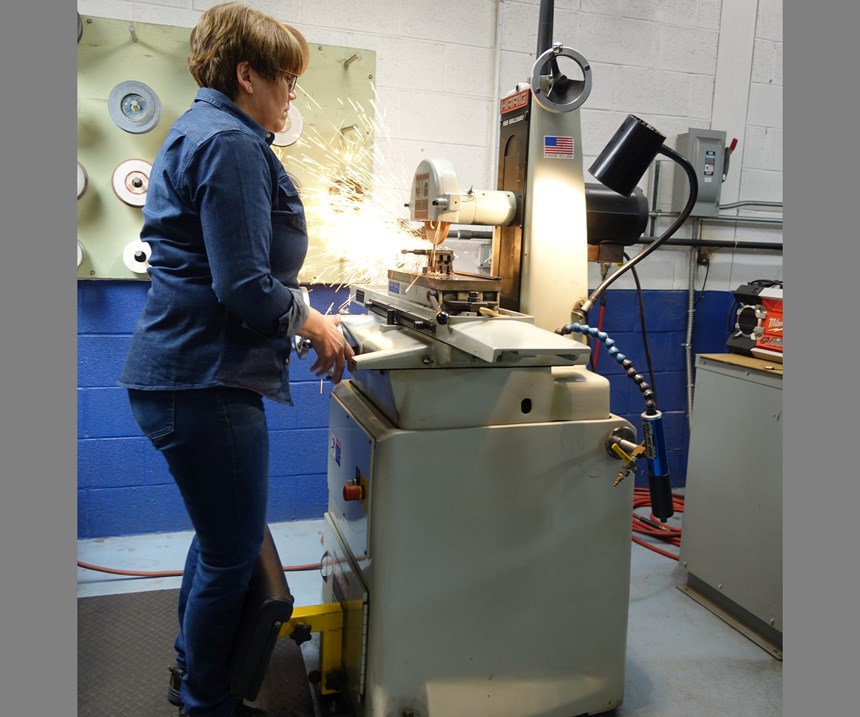

Walking into United Manufacturing Network, a small precision-grinding shop in Warren, Michigan, one immediately sees original World War II posters showing women at work. “This one was signed by the last surviving Rosies,” shop owner Cathy Sitek explains, smiling at a bright yellow Rosie the Riveter poster with black-marker signatures. One of the grinding machines in her shop, which served on a World War II battleship, very well may have been built by Rosies, she says. This thrills Ms. Sitek, an energetic woman with 35 years of grinding experience whose business is based on her skill and experience using decades-old precision machines. She prides herself on being an old-school machinist, but at the foot of every one of the machines in her shop is something new, the solution she now calls the “Standrite-Pro.”

Cathy grew up around machinists. Her father owned and ran a job shop, and he thought experience in the shop would help her find a path forward. “When I started working on the grinding machines, everything just made sense,” she says, and she never looked back. “My dad told me that if I wanted to own my own shop, I needed to learn how to run every machine, and that was fine with me.”

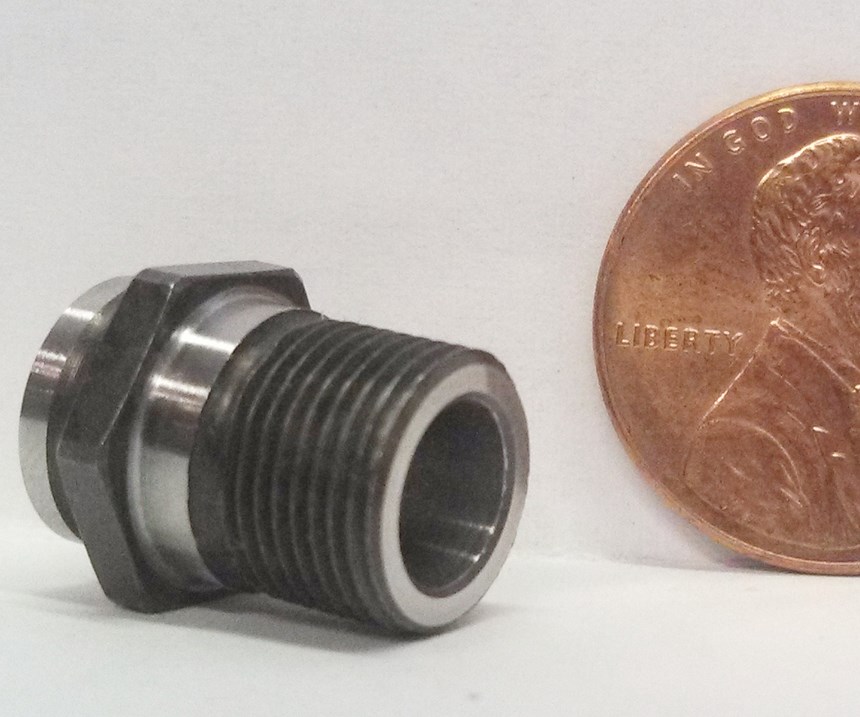

Eventually, Cathy did manage her own company. As the owner of United Gage, she manufactured precision gages for many years. Looking for a more profitable venture, she founded UMN as a distributor for machine tools, but in 2009 she had to shift gears as the recession struck. She purchased an aging jig grinder and placed a sign outside her building. She was able to repair the grinder and achieve tolerances as tight as 0.0001 inch. She slowly built up work, keeping the lights on but not making a significant profit. However, the profit margins improved when she married her husband Jerry.

“Instead, she did what toolmakers do and built a solution.”

Formerly a manager at a construction firm, Jerry Sitek is an experienced business manager. “We thought that if I handled the business side of things, and she took care of the machining, it would be a lot more profitable,” he says. The business purchased five more grinding machines and refurbished them to tight precision. However, as the number of orders increased, the company soon ran into trouble.

“We were expecting to hire help as we grew to take the burden off Cathy,” Jerry says. “But we couldn’t find anyone skilled with the manual machines that are our specialty.” As a one-stop shop for inner diameter, outer diameter, surface and jig grinding for short runs of special parts, the company gained a reputation for meeting demanding machining challenges, but the burden of 50 satisfied clients fell on Cathy.

In terms of pacing and time management, keeping as many as three machines running at a time was easy for Cathy. However, with the increased physical activity, she developed chronic pain in her back and feet. “I tried everything,” she says. “I did stretches. I put down floor mats. I even changed my shoes three times a day.” Nothing worked for her, which is far from unusual. Many machinists familiar with this pain simply endure it, she says, but Ms. Sitek was not inclined to hide or accept how she felt. Instead, she did what toolmakers do and built a solution.

A Machinist’s Approach to Medicine

Cathy worried that retirement might be inevitable. Aiming to forestall this, she brought a shower stool into the shop, intending to kneel a leg on it as she worked. As she did this, however, she noticed that leaning her shins against the stool was more helpful than kneeling on it. She found her pain gradually slipping away. Her feet and back were not bothering her as her shins made contact, and the next morning, she felt more energy and less pain than she had felt in months. She knew the stool had helped.

Intrigued, Ms. Sitek set to work using two essential prototyping tools: a pocket knife and some duct tape. An exercise machine from which she retrieved some cushioning did not survive, but using the shower stool, the cushions from the brutalized elliptical and some liberally applied duct tape, she put together the first prototype for what would become the Standrite-Pro. A simple stool with a front-facing, angled and cushioned panel, her first version did not look like much.

Within a week, she had swept her husband into her enthusiasm as her mood, energy and productivity soared, so the couple began work on improved prototypes. If such a simple thing could improve her health and productivity so quickly, they thought, perhaps it could help others. The Siteks formed the separate company Human Balance and Stability Systems (HBS Systems) to research her invention and turn it into a viable product while continuing to keep up with the daily grind.

“I think about the body like a machinist. All I see are structures.”

When a machine needs maintenance, a machinist consults the manual. Without a manual on hand, the Siteks independently researched human anatomy to understand why their system worked. As they learned more about the causes of chronic pain, they became acquainted with the concept of postural sway.

In biomechanics, postural sway is the horizontal movement of a standing person’s body as the body attempts to maintain its position. The body naturally makes minor adjustments to stay upright as the center of gravity sways subtly. These adjustments, though mostly unnoticed, cost energy and wear at the body’s connective tissue, causing inflammation and pain. Standing for lengthy periods slowly wears at the musculoskeletal system, leading to health problems such as back or foot pain. Leaning against the device the Siteks developed reduces postural sway by steadying the body where postural sway can be most damaging. Further, the angle of the cushioning reduces the weight load and keeps the knees from locking, reducing the strain on feet, legs and back. “I think about the body like a machine,” Cathy says. “All I see are structures.”

Moving Forward

The couple’s first beta user was a machine shop with a familiar problem: One of the shop’s oldest employees, a man whose technical skills were invaluable and irreplaceable, was having chronic pain push him toward retirement. The results were again nearly immediate. After continued use of the standing aid, the pain disappeared, and retirement was postponed. Furthermore, the machinist’s focus improved as he no longer had to deal with distracting pains. Beta users since then have included not just machine shops, but also office workers, chronic pain patients and a grocery store.

HBS Systems contacted an Oakland University professor to conduct a formal study of the device, and it revealed that the Standrite-Pro corrects posture multiple ways. First, it alleviates 18 percent of the pressure from the user’s weight, a significant reduction in strain on the user’s body. It also controls postural sway by providing a firm support, reducing the energy required to keep the user’s body upright and preventing inflammation. Furthermore, the angle of the cushion naturally corrects posture, reducing the pressure on the user’s knees, hips and lower back. HBS Systems is currently working with surgical-equipment manufacturers to gain Food and Drug Administration approval as a Class I medical device for use in operating rooms.

With a Michigan-based supply chain capable of producing thousands of Standrite-Pros a month, the Siteks are excitedly preparing to take on the enormous industry built around chronic pain. Cathy, however, seems most excited when she stands at one of her machine tools. For her, the Standrite-Pro is not simply a business opportunity, but the thing that keeps her working. She loves to run her machines, to be productive, and in that respect, she is not alone. The wonders of our modern world run on the work of machinists, and by reducing the toll this work takes on the body the Siteks hope to keep more machinists at the machine tools where they can find pride in the value their work creates, free of pain.