“Swiss Automatic” Grinder…Made in Jersey

This microgrinding machine uses a hydrostatic bearing akin to the guide bushing on a sliding-headstock, Swiss-type lathe to grind really long, really skinny parts.

Share

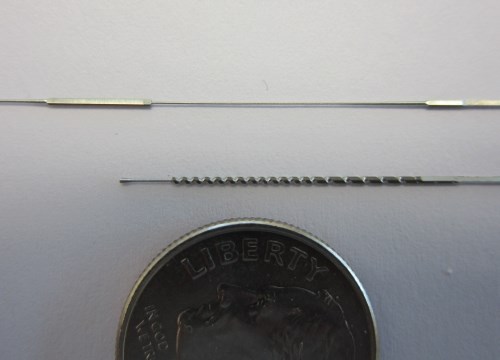

The CAM.2 microgrinding machine from Glebar uses a hydrostatic bushing to offer support very near the area of contact between the part and the grinding wheel. There’s pretty much no limit to the length of wire to be ground, as shown in these demonstration parts with tiny ground flats, tapers, threads and so on.

Glebar, a New Jersey manufacturer of OD grinders, plunge grinders and other types of grinders, developed an interesting technology for grinding long, small-diameter parts. We’re talking workpiece stock as small as 0.005 inch in diameter and a minimum grinding diameter of 0.0005 inch for applications such as medical guidewires that can range to 16-feet long.

The way it does that is by applying a concept that’s similar to a sliding-headstock, Swiss-type lathe and its signature guide bushing. Learn more.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.png;maxWidth=300;quality=90)