Share

From March 15 to April 15, the Taiwan External Trade Development Council (TAITRA) held an online version of the organization’s signature Taiwanese International Machine Tool Show (TIMTOS) demonstrating the technical capabilities of its member companies. Numerous Taiwanese manufacturers of machine tools and machine tool components participated, displaying a variety of advanced manufacturing technologies.

A key feature of the show was each company’s embrace of data-driven manufacturing. This, alongside the event’s emphasis on automation solutions and other advanced machinery suggested the participating companies intend to compete with high-end Japanese and German manufacturers in the U.S. market.

Turning and Machining

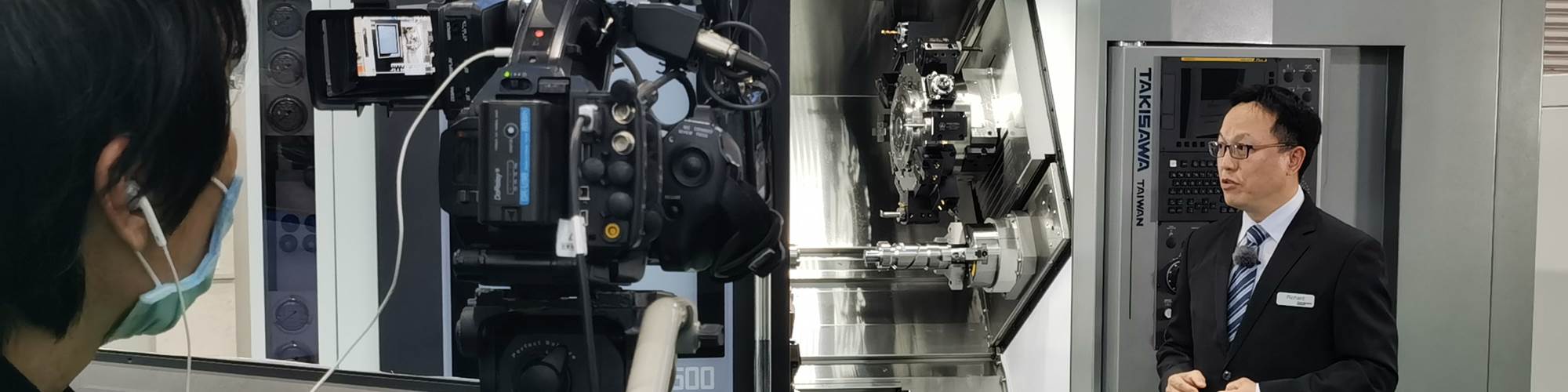

This year’s TIMTOS was a virtual event that provided each of the participating companies with the chance to showcase some of their products. Taiwan Takisawa Technology discussed an array of mill/turn machines and precision lathes. Photo Credit: TAITRA

Taiwan Takisawa Technology (TTT), displayed multiple turn/mill centers in its presentation, including the UX-2000 ST, a five-axis simultaneous turning/milling machine. With an integrated automatic tool changer (ATC) and a 240-degree rotating B-axis milling head, this machine can perform complex machining and turning operations with minimal operator oversight. Both this machine and the company’s EX-2000 turn/mill are capable of high-speed machining operations in addition to precision turning.

Additionally, high-end turning centers were on display, including TTT’s AX 1500, an ultra-precision lathe designed for the optical industry and capable of turning at a 0.3-micron accuracy in roundness and cylindricity. It can attain a surface roughness of plus-or-minus 5 nanometers, reducing or even eliminating the need for finishing on a separate machine.

Many companies discussed five-axis machining. Campro Precision Machining, for example, showed the NU-630, a triple-column, five-axis machining center with a swivel head. Photo Credit: TAITRA

The presenting companies also displayed a wide variety of five-axis machines, with nearly every machine tool manufacturer having at least one option. Campro Precision Machinery, for example, showed the NU-630, a triple-column, five-axis machining center with a swivel head. According to the company, the machine was designed with thermal compensation in mind and has built-in cooling systems for the spindle. The arrangement the company had on display came equipped with a T-Series tool management system that uses ID numbers to identify up to 6,000 tools, as well as which users load tools or operate the machine.

Another example is the CN-4050 from Asia-Pacific Elite Corp. (APEC), a gantry-style high-speed, five-axis machining center designed for machining large composite parts for the aerospace industry. The machine is equipped with built-in hood for controlling dust and other particles produced by machining, and it comes equipped with a large pallet changer.

One theme that united the presentations was the focus on advanced technology, much of it comparable to what might be expected from Japanese and European manufacturers. By showcasing these machines, TAITRA and its members seemed to be making a statement emphasizing high-end machine tools. Machines shown were automation-ready and capable of using multiple advanced machining strategies, aimed at machine shops manufacturing complex parts with precise tolerances.

Advanced Solutions for the American Market

Nearly every company demonstrated automation solutions for pairing with its machines. Machines such as the UX-2000ST from TTT have standard automated tool changers, while the CM4050 from APEC had a pallet system designed to accommodate large parts. Additionally, component manufacturers like GMT Global focused on automation solutions that were not machine-specific, such as GMT’s robotic components.

Another telling trend was the companies’ focus on Industry 4.0 solutions. Every company at this event had a data-integrated feature for its machines. Buffalo Machinery, for example, displayed the Axile DC-12, a large five-axis machine center with 86 inches of travel along its longest dimension and a max workpiece diameter of 51 inches. The machine comes standard with an “intelligent” monitoring system that both measures and analyzes data from the machine.

On the other hand, Gifu – a manufacturer of tool magazines – highlighted the predictive maintenance capabilities and collision monitoring system that come standard in the magazines. The resulting impression is that we are approaching a state in which every major machine component can provide helpful, actionable feedback to operators to avoid downtime.

Axile’s iAutomation system is integrated with its machine-monitoring solutions to provide feedback on all machines linked to it. The company’s palletized automation system can link as many as three machine tools with a single pallet system. Photo Credit: TAITRA

Buffalo Machinery demonstrated both automation and data-driven manufacturing with Axile’s iAutomation system, an interconnected pallet-changing system that can connect up to three machine tools to a single pallet changer. The company’s ART monitoring system connects most of its machines, including this automation system, providing machine monitoring and even identifying potential problems for preemptive maintenance.

This focus on automation and interconnected IIoT systems once again reinforces the main thrust of the event — how Taiwanese manufacturers are supplying equipment to support advanced manufacturing strategies. However, leaving that intended message aside, the show’s focus also demonstrated how vital these technologies have become in metalworking. Even small shops have access to advanced automation systems and data-driven technology, and as more shops experience and come to expect the advantages of these technologies, the demand for them increases.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreRead Next

Standardizing on the Mazak Brand Eases Shop’s Training Process

Choosing a single brand of machine tools enables Ketchie Inc.’s operators to be self-sufficient. They can quickly learn to set up and program virtually any machine in the shop.

Read MoreWeingärtner Mill-Turn Widens Plasticizing Screw Production Range

Weingärtner’s custom Pick Up mill-turn center for injection mold machine manufacturer Arburg has widened the range of plasticizing screws Arburg can produce.

Read MoreBrass Machining Optimizations Save Job Shop Time and Money

With the help of TechSolve Inc., Nolte Precise Manufacturing Inc. optimized a brass part and saved $22,000 while opening up significant extra production time.

Read More

.png;maxWidth=300;quality=90)