Tips for Anticipating Hole Conditions

When measuring an ID with an indicating plug gage, it is OK to slow down to learn more about the hole being measured and explore for extraneous conditions.

Share

For most users, a fixed-body indicating plug gage, whether mechanical or pneumatic, is probably the easiest gage to use to get a fast, high-precision and accurate hole diameter. Simply insert the plug gage into the hole and read the deviation from the master to get the diameter.

However, the real advantage of these types of gages over an adjustable bore gage is that it is a lot easier and faster to determine hole conditions such as ovality, taper, hourglass or bell-mouth shape. All it takes is a further exploration of the bore.

The need for speed is certainly the cry of production manufacturing, but when measuring an ID with an indicating plug gage, it is OK to slow down just a little to learn more about the hole being measured. Take the time to explore for extraneous conditions, and should something be discovered, find the minimum diameter, as it generally will have the greatest effect when a shaft or cylinder is assembled to the bore.

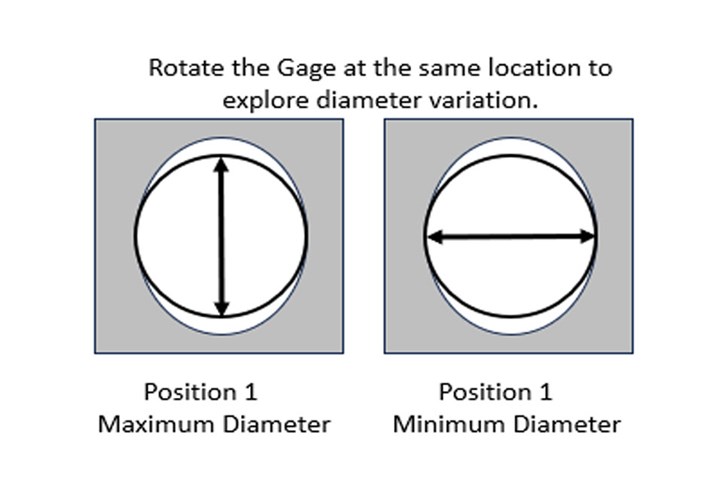

First, simply rotate the plug at the same level in the bore, searching for the minimum and maximum conditions. This is easy to follow on an analog scale.

Hopefully, both readings are within the diameter tolerance. If not, this could indicate that something is awry with the manufacturing process. As mentioned above, it is probably a good idea to note specifically where the minimum diameter is located, as it may help fix or prevent future problems.

This diameter variation — the difference between the minimum and the maximum diameters — is often referred to as total indicator runout (TIR). With many digital indicators or bench amplifiers, there are built-in functions that can be used to “remember” this difference, so the operator does not have to manually calculate it.

Some confuse TIR with “roundness.” This is not the case; true roundness is different and defined in various international standards. However, some will use TIR at the point of manufacture as a trigger point for further measurements if the variation becomes significant compared to the diameter tolerance.

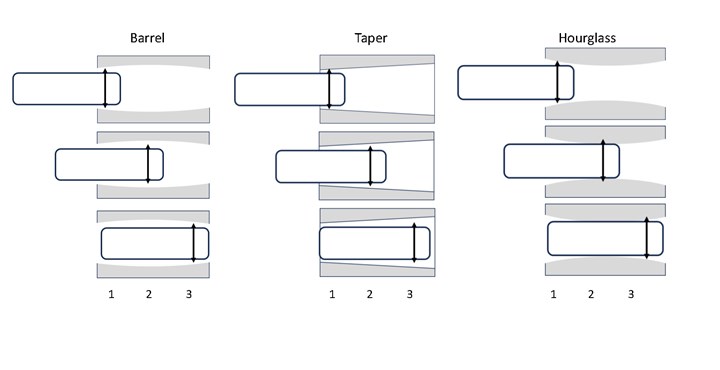

The next step in learning more about the hole is to start exploring it axially, say at three points along the length of the bore, and compare the three diameters. By comparing these diameters, it becomes easy to identify the presence of an hourglass, bell mouth or taper within the form of the hole.

As the figure below illustrates, the fixed plug gage can disclose these conditions with exploration at different depths. All of these are apt to appear within every hole manufactured, but the degree of the form error compared to the diameter tolerance is most important.

By exploring the hole axially at multiple locations, form errors such as hourglass, barrel or taper can be found. Photo Credit: Mahr Inc.

Some users will check these types of parts both radially and axially, exploring for the minimum and maximum values — or an overall diameter variation. As with Roundness, some might say this exploration is an indication of cylindricity. Cylindricity is a well-defined form parameter, and our exploration would not be the proper way to check this. However, use this as a trigger for further analysis if the variation is a large part of the diameter tolerance.

These small deviations in form are very critical in machine design, where surface contact is required for a shaft, and bearing is required. Conditions like the ones above would result in very uneven loading on the parts, which ultimately leads to vibration, faster wear and even premature breakdown. Taking a little extra time to explore critical components with a fixed plug bore gage can help to prevent these conditions.

But what if — even after a close inspection of the diameter and a thorough exploration of the part — there are some mating issues with the hole and its shaft? This may come down to other form errors where the two-point fixed plug gage just cannot measure.

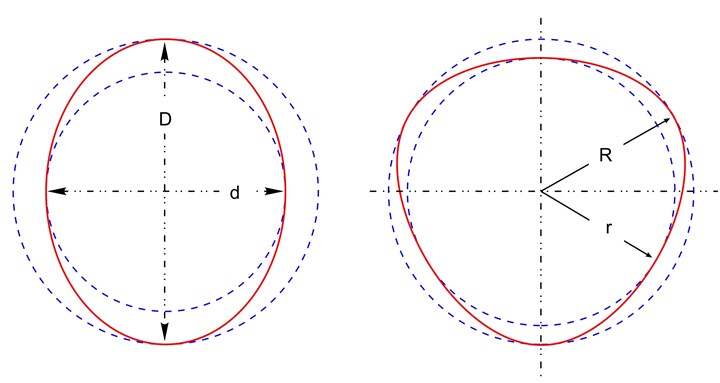

A two-point fixed plug gage is great for inspecting for a minimum and a maximum diameter, as shown in the first figure above. The figure shows a hole that has two lobes; thus, it is a hole with an even number of lobes. A two-point plug can easily find this diameter variation.

But try to measure a hole that has an odd number of lobes — three, for example — and the gage is apt to show the part at the correct diameter and to have very little diameter for form variation. This is because a two-point plug gage cannot measure this condition.

A two-point gaging system is best for even lobbing conditions, while a three-point gaging system is best for odd lobbing conditions. Photo Credit: Mahr Inc.

A fixed plug gage can provide more information about a hole than just the diameter at a single location. By making an effort to explore the hole, further details about the part shape can be made, as well as potential problems with mating parts.

Related Content

Turning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreUsing Digital Tap Testing to Measure Machining Dynamics

Tool-toolholder-spindle-machine combinations each have a unique vibration response. We can measure the response by tap testing, but we can also model it.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreA 100-Year-Old Measurement Tool That is Still Used Today

The reed mechanism was a breakthrough in high-precision measurement and is still used today for sub-micron or even nanometer resolution applications.

Read More