Toolpath Engine Benefits Extend Beyond Cycle Time

Available from Celeritive Technologies, VoluMill is a plug-in toolpath engine designed to maintain a constant load on the cutting tool and enable machines to operate at peak efficiency. However, as the experience of this firearms manufacturer demonstrates, its benefits extend beyond improved cycle time, tool life and metal removal rates.

Share

With a culture that emphasizes quality and continuous improvement, McMillan Machine Company is always willing to try out new technologies and techniques, says general manager Duncan Davis. However, when Mr. Davis was offered a free, 30-day trial of Celeritive Technologies’ VoluMill toolpath engine in December 2009, he couldn’t possibly have conceived of the extensive benefits the system would provide. In addition to the promised improvements in tool life, metal-removal rates and cycle time, the CAM system add-on prolonged machine tool spindle and coolant life while reducing energy consumption, labor costs, machine wear and lost quotes. “We decided to purchase it after the first week,” Mr. Davis recalls. “The results were so dramatic that one order paid for the software. It’s been all profit after that.”

Mr. Davis’ shop is one of seven companies in the McMillan corporate family. The group traces its roots to 1973, when founder Gale McMillan began producing his own firearm stocks for competitive bench-rest shooting matches. Other shooters, always in search of a competitive edge, began asking him to produce stocks for their rifles as well. The brand’s reputation continued to grow during the next few decades, and today, its products are the weapons of choice for the Navy Seals and other elite American troops.

McMillan Machine Company was born in 1987 when Mr. McMillan decided that producing firearms in-house, as opposed to buying, dismantling and rebuilding components from Remington, would improve quality while saving time and money. Although the company has produced aftermarket parts for Harley-Davidson and components for Cessna, its primary focus is weapons systems. Barrels, firing components, housings, chassis, mounts, adapters and couplers comprise the majority of its workload.

Mr. Davis was prompted to try VoluMill by his Gibbscam CAM software reseller, John Gulstad of Technical Manufacturing Information (TMI). Mr. Gulstad, a firm believer in VoluMill, says every one of his Gibbscam customers that has tried the plug-in—including McMillan Machine—ended up buying it. “It’s probably the most dynamic and important CAM development in many years,” he says.

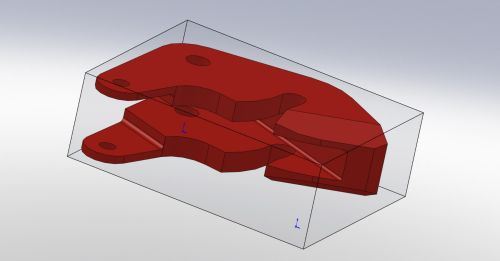

The plug-in toolpath engine is designed to replace traditional roughing methods in applications that require prioritizing ease of programming, reduced cycle times, extended tool life and reduced stress on machine tools. According to developer Celeritive Technologies (Cave Creek, Arizona), the software plans tool paths based on the capabilities of the machine and cutting tool, regardless of the shape being cut. In contrast, traditional toolpath strategies are derived from the geometry being machined.

The software’s benefits stem primarily from its ability to maintain a consistent metal-removal rate, which is determined by the user according to the particular combination of machine, cutting tool, geometry and workpiece material. It does this by dynamically adjusting feeds and speeds and by using smooth, flowing tool paths that avoid sharp corners and other features that can subject the cutter and spindle to extra stress from cutting forces. Managing material-removal rates in this way keeps the load on the tool constant, avoiding premature wear while enabling the use of more aggressive machining parameters, regardless of workpiece geometry. The result is prolonged tool life and reduced cycle time, the developer says.

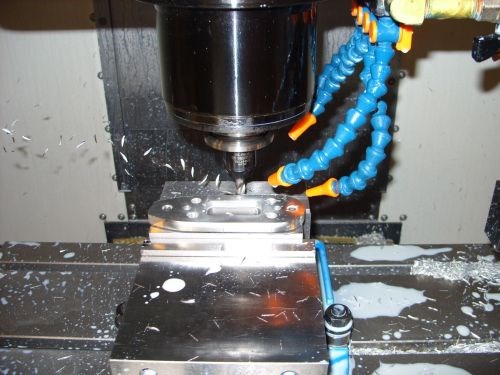

The first McMillan job to benefit from VoluMill—an order that brought in sufficient revenue to pay for the software—was a 6Al4V titanium mount component that required a great deal of machining and was hard on tools. Originally, the part took 80 minutes to rough at 1,225 rpm, 6.25 ipm, a 0.315-inch axial cutting depth and an 0.22-inch radial cutting depth. With VoluMill tool paths, the shop reduced radial cutting depth to 0.35 inch and increased axial cutting depth to 1.18 inch, spindle speed to 3,056 rpm and the feed rate to 100 ipm. Both strategies employed the same cutter, a ½-inch-diameter, five-flute, solid carbide end mill.

Using the new parameters—which, the company says, would not be remotely possible with traditional tool paths—produced a nearly tenfold increase in material removal rate. As a result, roughing time was reduced to 30 minutes per part. Tool life also improved by a factor of 10, from four parts per tool previously to 40 parts per tool with VoluMill.

As another example of efficiency gains gleaned from VoluMill, Mr. Davis cites a part that required machining a 28-pound block of 17-4 stainless steel down to a 2.8-pound finished part. Based on the shop’s established practices before implementing the plug-in, Mr. Davis estimates that each part would have required machining with a series of five indexable tools. Operations with the first tool alone would have taken 2 hours and 20 minutes. With VoluMill, however, the shop could complete the whole job in 2 hours, with the bulk of the material removal taking 1 hour and 15 minutes. As a result, the shop was able to save an estimated $4,800 in machining time and $2,400 in tooling costs.

The company has also applied VoluMill tool paths on jobs that it had already accepted and for which it had already established prices. “We reprogrammed some jobs that were not so profitable in the past, and I can now manufacture them more efficiently and get a good margin,” Mr. Davis says. In fact, recent savings from reprogramming three different parts using the toolpath engine added up to $8,400.

Mr. Davis estimates that in the first four months of using the toolpath engine, the company has saved $5,000 in programming time and 200 hours—or $16,000—in cycle time. Moreover, increased tool life has saved the company $3,000 in tool costs. However, while significant, these cycle time and tool life improvements constitute only a portion of VoluMill’s impact on the bottom line.

Although difficult to quantify, the most obvious benefit is VoluMill’s impact on machine tool wear. Mr. Davis says that tool paths generated by the plug-in reach a maximum spindle load of 18 percent in titanium, compared to 70 or 80 percent with traditional tool paths. “Common sense tells me that it’s saving wear and tear on our machines,” he notes. In a sense, the software places less “wear and tear” on operators as well. Ease of programming means more jobs can be completed in less time, freeing employees to attend to other duties. In fact, Mr. Davis says the company saves $900 to $1,000 per week on labor costs.

These time savings have also facilitated more accurate quotes. “It’s safe to say that we’ve seen a 5- to 10-percent savings in lost quotes,” he says. “I’ll generate a couple of simple geometries in Gibbscam and run VoluMill on it just to look at the run time. So, I’ve already got part of the job programmed before I even get it, and it only takes 30 minutes to give me a ballpark of where I’m going to be on run time. If the customer gives me a model on which to base my quote, it’s even better.”

The company also realized a 65-percent savings in energy costs because machines run more efficiently with the new tool paths and take less time to complete a job. Coolant costs have decreased by an estimated 20 to 25 percent, thanks to consistent tool loads and shallower radial cutting depths. “The solvent isn’t breaking down as fast and is lasting a lot longer,” Mr. Davis notes.

“VoluMill impressed us enough right off the bat that I didn’t even bother looking at other options,” he concludes. “It did more than I expected it would do.”

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read MoreThe Smarter Way to Take Full Control of Your CNC Machine Shop

Designed to bridge the gap between CAM programmers and shop floor operators, SolidShop provides a seamless, real-time solution for managing G-code, tracking production and eliminating costly mistakes.

Read MoreRead Next

An Alternate Route For Generating An Alternate Tool Path

A universal toolpath engine for roughing pockets optimizes cycle times by maintaining a constant material removal rate regardless of part geometry. This toolpath engine is not a CAM system. Instead, users pay a monthly fee to upload geometries to a secure Internet server and quickly receive tool paths that can be used with any CAM system.

Read More

.png;maxWidth=300;quality=90)