MMS Blog

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

Read MoreChoosing the Right Machine for Turned and Milled Medical Parts

In the medical industry, tight tolerances and exacting specs are the norm, which means that machine selection is vital to ensure that throughput is high and the job is profitable.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreAutomation Solutions, Multitasking Machines Take Center Stage at Machine Fest 2023

Methods Machine Tools' Chicago-area Machine Fest saw over 15 live demos and more than 20 industry vendors over its two days, with a noticeable presence of automation solutions and multitasking machines.

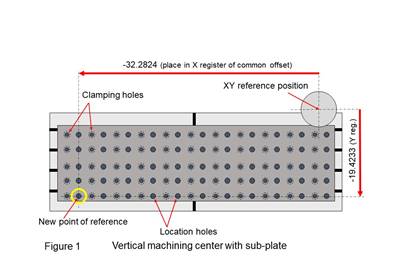

WatchThe Best Point of Reference for Program Zero Assignment Entries

Correctly specified program zero assignment and coordinate position values enable the CNC to determine how far to move the cutting tool during each positioning motion.

Read MoreMake the Most of Your Interactions With Salespeople

Don’t miss out on products and knowledge that could help your company.

Read MoreThere's Your Waste, Shaw! An Argument for Shop Reinvestment

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

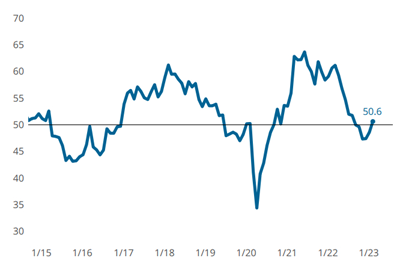

Read MoreMetalworking Activity Crept Into Growth Mode in February

The GBI closed at 50.6 in February, calling for cautious optimism.

Read MoreHow Aneesa Muthana Found Her Own Path in Manufacturing

From working phones at 11 years old to reinventing her own business during a downturn, here's how Aneesa Muthana created her own path in manufacturing.

Read MoreMade in the USA - Season 2 Episode 4: A Measured Approach

The L.S. Starrett Co. has been manufacturing precision measurement tools in Athol, Massachusetts, since 1880. Attention to U.S. manufacturing often focuses on reshoring manufacturing from other countries, but Starrett never left. The facility in Athol employs hundreds and produces thousands of tools that remain vital for measurement in machining and other fields.

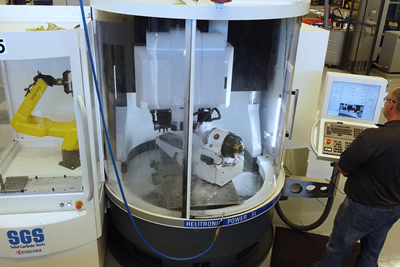

ListenRebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

Read MoreHandling the Growth of an Adaptable Automation System

Implementing an adaptable automation system helped this shop stay on top of seasonal swings in demand. To effectively grow this system, it had to keep several considerations in mind.

Read More