CAD/CAM Software Brings Process Automation for Mold Design, Machining

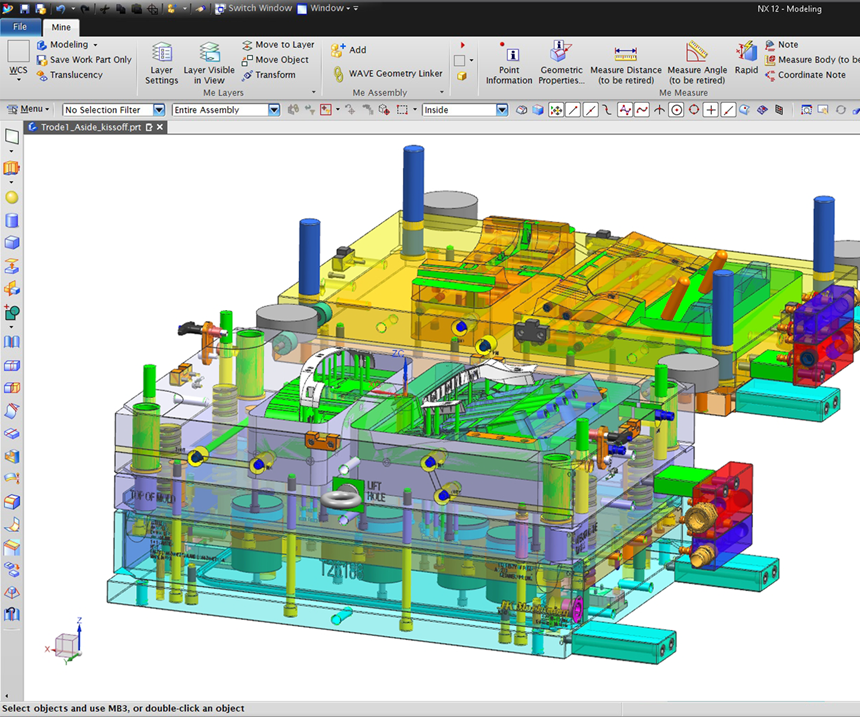

The NX software suite from Siemens provided this moldmaker with tools that simplified and automated steps in the mold design process.

Share

With a focus on increased quality and compressed build times, companies like JK Machining, which specializes in designing and manufacturing plastic-injection molds, must strive to meet customer demands. The company invested in advanced machining capabilities; but by upgrading its CAD/CAM system to a mold-specific software suite from Siemens PLM (Plano, Texas), the company was able to deliver quality molds at a reasonable cost.

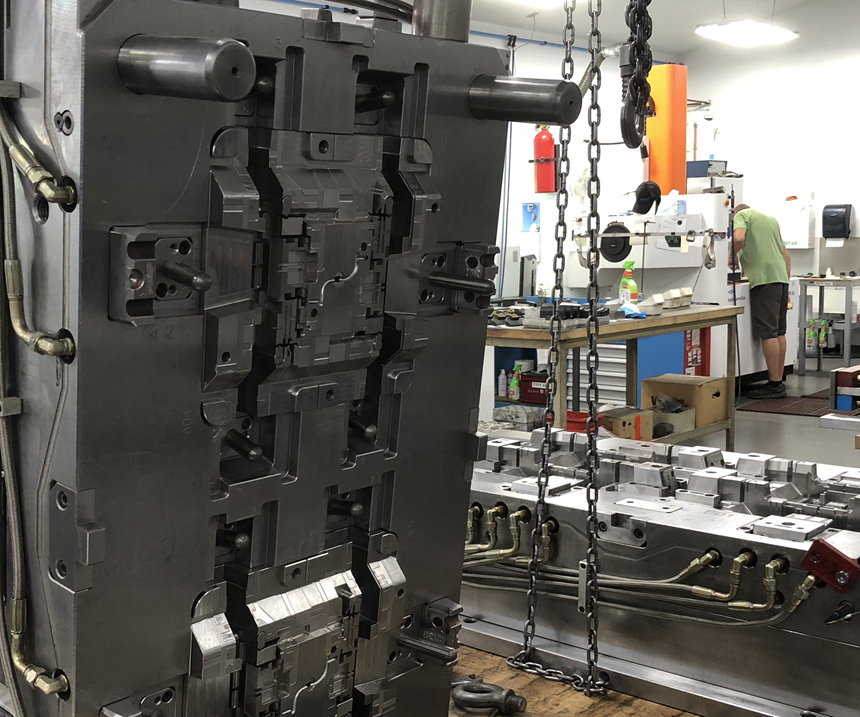

Founded in 1980 and located in Kalamazoo, Michigan, JK Machining’s 15-employee company focuses on class-101 molds—high-production molds with fast cycle times made from high-quality materials and designed for 1 million or more cycles. Its automotive customers are Tier-One and Tier-Two suppliers producing mostly air conditioning outlets, trim bezels, cup holders and other interior components. The company also makes molds for the medical device industry. Both sectors demand high quality, better mold-parting lines, better finishes, tighter tolerances, timely delivery and reasonable costs. Such demands have only grown.

According to Henry Kalkman, president of JK Machining, the company used to have 18 to 22 weeks to build a mold for the automotive industry. “Now that’s down to 10 to 12 weeks,” he says. “All of our customers want to get to market faster. Offshore moldmakers have an advantage in cost, and are bringing up their level of quality. They are our main competitors.”

Understanding Software Needs

To meet these demands, the company has invested in advanced machining capabilities. It has two high-speed Röders vertical machining centers; two Milltronics machines that are used primarily for drilling cycles and roughing; and single three- and five-axis machines used for finishing mold cavities and cutting electrodes for EDM. However, the company found itself lacking the right software to take full advantage of these machines.

Consequently, JK Machining sought to upgrade its CAD/CAM capabilities to improve efficiency and competitiveness. Formerly, it had used separate software systems for the design and manufacturing stages, which meant exporting CAD data in a neutral exchange format, then importing the data into the CAM system for numerical control (NC) programming. This transfer and translation of data introduced additional steps that hampered productivity and provided room for errors to worm their way in. Furthermore, it complicated design changes, which were difficult to track and implement correctly through the process as a whole.

On top of these inefficiencies, the company’s NC programming software proved difficult to operate on five-axis machines, and few customization options could address speed and efficiency requirements. With these problems hampering both ends of the process—design and production—it became difficult to deliver timely, quality molds at a reasonable cost.

Finding a Solution in Process Automation

JK Machining selected the NX software suite from Siemens PLM Software, which includes specialized mold-design features in addition to traditional CAD/CAM capabilities. Key software characteristics automate parts of the mold-development process from design to manufacturing. CAD functions include working with geometric models provided by customers as well as mold-specific capabilities that support an efficient design workflow. Five-axis and high-speed machine programming functions in the CAM software enable the company to take full advantage of its advanced machine tools. By fully integrating mold design and machining, the software enables users to edit a CAD part, then seamlessly go back and forth between CAD and CAM, virtually eliminating room for errors. With this integrated system, the company established a digital thread that enabled process automation throughout design and manufacturing.

The typical mold-design process at JK Machining begins when customers send CAD models and requests for quote. The CAD models are usually in the STEP neutral interchange format, and the company imports the geometric data into NX. After winning a project, the company uses the specialized mold-design features of NX Mold Wizard to create the mold base and design cores, cavities, runners, cooling lines and other features quickly and efficiently. The software points out undercuts and places where more draft is necessary. The designer can look for thin or thick walls and automatically determine the mold’s total weight and center of gravity. With mold features readily identifiable, the design process progresses quickly.

The software can automate other aspects of mold design, such as bill of materials creation, and users can save time by automating repetitive tasks with journaling and macro capabilities. The user can perform a task once, record it with journaling and save it as a macro to use on the next project. Additionally, the mold design libraries enable users to quickly compare revised and past part models, saving time on the updating process.

Integrating Machining with Mold Design

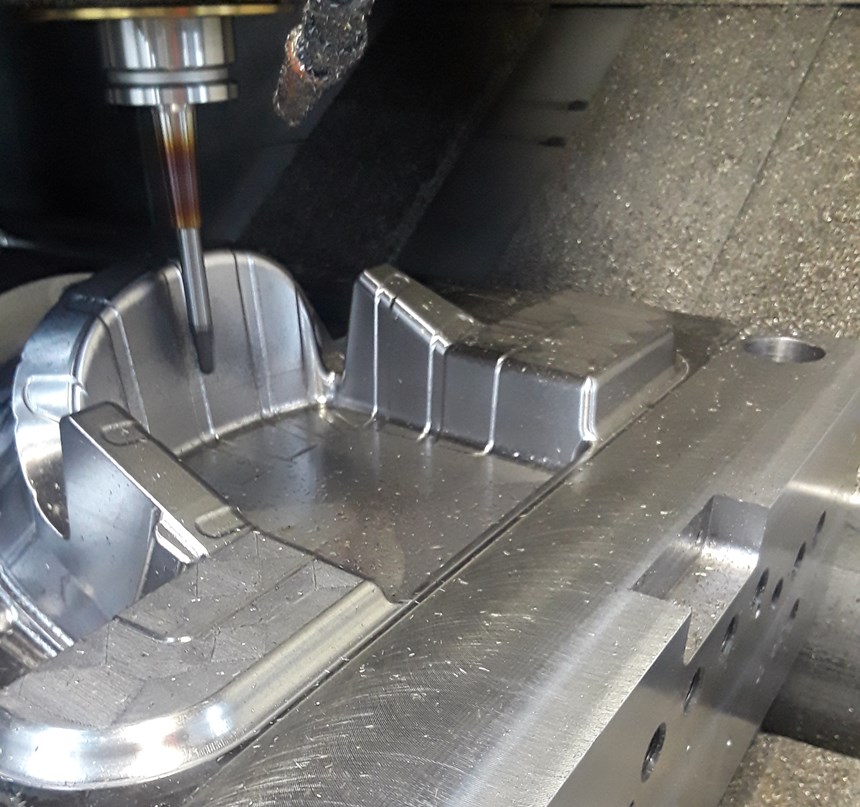

The shop uses NX CAM to program all milling operations involved in mold and die manufacturing.The NC programmers work directly from the CAD model and use NX design functions to design electrodes and prepare models for machining. The CAD tools are used frequently to extrude, unite and close gaps, and the “optimize face” capability can heal questionable part geometry without forcing the user to go through a multi-step process.

The software also provides open automation and customization tools that enable users to tailor it to specific requirements.

Process templates enable NC programmers to use proven cutting methods and tooling. Instead of working out and manually entering the same parameters for diameters, depths of cut, and feeds and speeds for every job, they can reuse saved templates to create a tool path in a matter of minutes. Over time, the library of proven machining cycles users generate can include operations like roughing, semi-finishing and finishing, enabling the shop to automate NC programming.

Achieving High-Speed and Five-Axis Machining

NX CAM is designed to enable multiple kinds of advanced machining, including high-speed machining, a key technology for moldmakers who need to quickly machine surfaces to a near-mirror finish. It automatically provides radii in addition to toolpath approaches and exits, lending itself to fast, smooth cutter paths. It can keep the machine’s cutting speeds and feed rates high while eliminating sharp corners, sudden stops and pauses on the steel or graphite. The three Röders machines can consistently achieve a quality surface finish, eliminating benchwork and saving time, which improves the customer acceptance rate.

Additionally, the software includes tool-tilt controls, which make it easier to take advantage of five-axis machining. It automatically converts three-axis tool paths to five axes in order to efficiently machine molds with deep cavities. With tilted-tool machining, the shop can use shorter tools to reduce vibration, minimize tool deflection and improve surface finish. “Without tool tilt, we would have to take the cutter to the grinder and relieve the neck,” says a senior programmer. “When you’re cutting an electrode with a 0.032-inch-diameter cutter that’s hanging out an inch and a half, you have to slow down the feed rate by a third and take smaller cuts. But with the five-axis tool-tilt method in NX CAM, we improve mold quality while reducing machining time by up to four times.”

Mr. Kalkman is pleased with the results. “In the past, we were just using three-axis machining, and now we’ve moved to five-axis. We are even looking into robotics to further automate the process.” He says that automating the mold-development process has helped to build his company’s reputation and keep the shop competitive.

Related Content

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreEmbracing Automation: Strategies for Small to Medium-Sized Machine Shops

Business drivers for automating to help navigate workforce challenges and boost profitability.

Read MoreAerospace Shop Thrives with Five-Axis, AI and a New ERP

Within three years, MSP Manufacturing has grown from only having three-axis mills to being five-axis capable with cobots, AI-powered programming and an overhauled ERP. What kind of benefits do these capabilities bring? Find out in our coverage of MSP Manufacturing.

Read More

.png;maxWidth=300;quality=90)